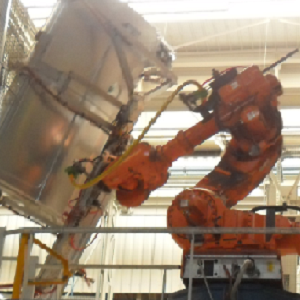

Safe Heavy Payload Tool Changer Solution without Yield Compromise

Yield, Safety, and Repeatability are key factors of any production chain equipment. Especially in the automotive industry where production flow is high while robots EOAT payloads can reach hundreds of kilograms.

With more than 20 years of experience in industrial processes, PES provides a safe, reliable and fast tool changing solution and this even with large and heavy EOAT. It embeds electrical and pneumatic safety loop coupled to a cam lock design that allows a repetitive and safe tool change

Electrical Features

- Quick connection of motors (power and control)

- Quick connection of Field Buses or discrete I/Os

- Tool presence and docking monitoring

- Tool changer status control and monitoring through discrete I/Os or Fieldbus

Mechanical Features

- Cam lock mechanism with integrated wear compensation

- Tough design for payloads up to 800kg and more

- Custom robot interface available

Interesting Options

- Tool coding

- Docking station with a compliant fixture

- Tool protection cover for dusty environments

- Powered docking station to keep tools communication alive and avoid re-start latency

Advantages

- Manual or software unlocking nearly impossible once locked and under safety loop monitoring

- Continuous tool changer status monitoring (air pressure, sensors, etc.)

- Low cycle time, reliable and repeatable

- Complete turnkey solution

Benefits

- Enhance robot and production line capabilities

- Help to save floor space

- Mitigate energy consumption (no energy needed for a docked tool)

- Reduce integration costs

- Minimal maintenance costs

Facts & Figures

- With a good integration, tool change can be performed in less than 5 seconds

- Cam locking mechanism can outreach 5 millions of operation cycles

- PES Tool Changing Solution complies with Level-D safety performance level requirements

- PES is a leading supplier of tool changing systems in the automotive industry worldwide for more than 20 years with hundreds of units in operation