Our Solutions

- Bin-picking applications

- Magnetic Handling Applications

- Modular EOAT

- Destacking/Thin Sheet Application

- Collaborative robots

Brands

Our product range

Support & Services

Our Solutions

- Packaging Machines Applications

- Medical/Parmaceutical Equipment

- Hose and Cable Reel Applications

- Multimedia and Entertainement Equipment

- General Industry Equipment

- Test Benches Applications

- Harsh Environment Applications

Brands

Our Solutions

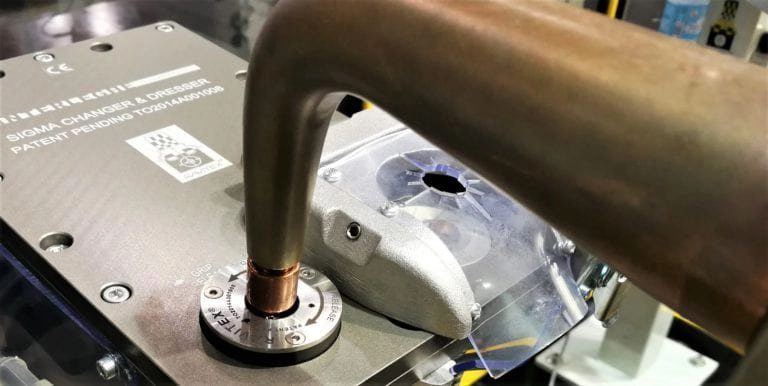

- Welding Process Applications

- Handling Applications

- Riveting/Gluing applications

- Vision or inspection applications

- Stamping line applications

Assemblies

Support & Services

Components

Leak detector

Related industries

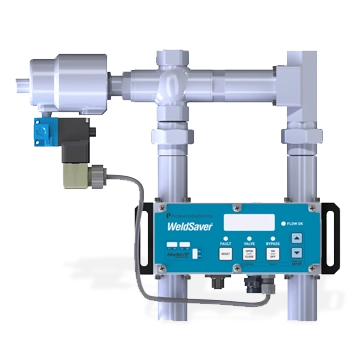

WeldSaver™ 6 with eVac™

The Proteus WeldSaver™ 6 with eVac™ Coolant Retraction Module is for water control in order to control flow, leak detection and to prevent catastrophic coolant dumps at the time of robotic automotive welding operations.

It has been over 25 years, the Proteus WeldSaver is known as the industry's leading water control device to control flow and provides the fastest leak detection in automotive welding. By integrating a new with eVac™ Coolant Retraction Module, Proteus adds intense protection against coolant dumps while doing welding operations by retracting water from the cooling gun circuit.

Intelligent Leak Detection

The proprietary detection algorithm of the WeldSaver rapidly identifies flow velocity changes, which differentiate true leaks from pressure-, temperature-, and motion-induced effects, identifying a leak condition within 0.3 seconds. In the event of a cap loss or other leak, the WeldSaver signals a state change to immediately in order to stop the welding process, simultaneously closes an attached shutoff valve, and retracts water from the cooling gun.

No matter monitoring coolant flows to weld guns or to the entire weld cell cooling circuit, the WeldSaver with eVac rapidly and reliably observe changes in flow continuity created by slow leaks, cap loss, or other catastrophic events and significantly reduces or prevents coolant dumps on expensive cap-changers and weld cell floors.

WeldSaver 6 with eVac Key Features

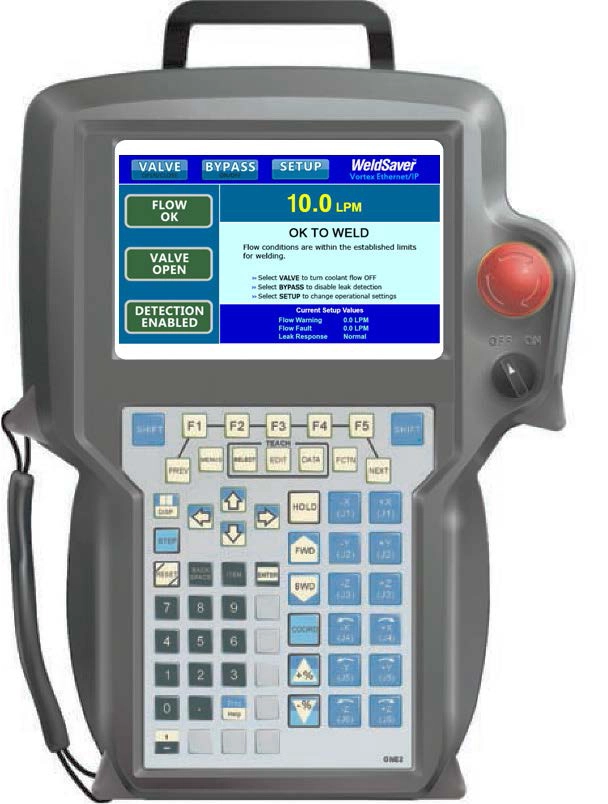

- Constant indication of coolant flow rate and temperature on browser-based interface - including teach pendants

- Proprietary leak-detection algorithm sends alarm to weld controller in less than 0.4 seconds

- When cap gets loss, flow shuts off in less than 1 second or other loss of flow continuity to reduce coolant dumps on floor or equipment by retracting water from the cooling gun circuit

- EtherNet/IP™ and PROFINET® control interface options

- User-selectable operating parameters and alarm settings

- Remote control of valve and system states to support weld guns and cap changers

- Flow ranges from 6-50 LPM / 1.5-13 GPM

- Liquid temperatures from 4.0-110 °C / 39-230 °F

The WeldSaver graphical user interface provides information on device status in real time, with clear visual indicators and descriptions. The interface can be accessed over a network using most JavaScript™-enabled web browsers by entering the working IP address of the device.

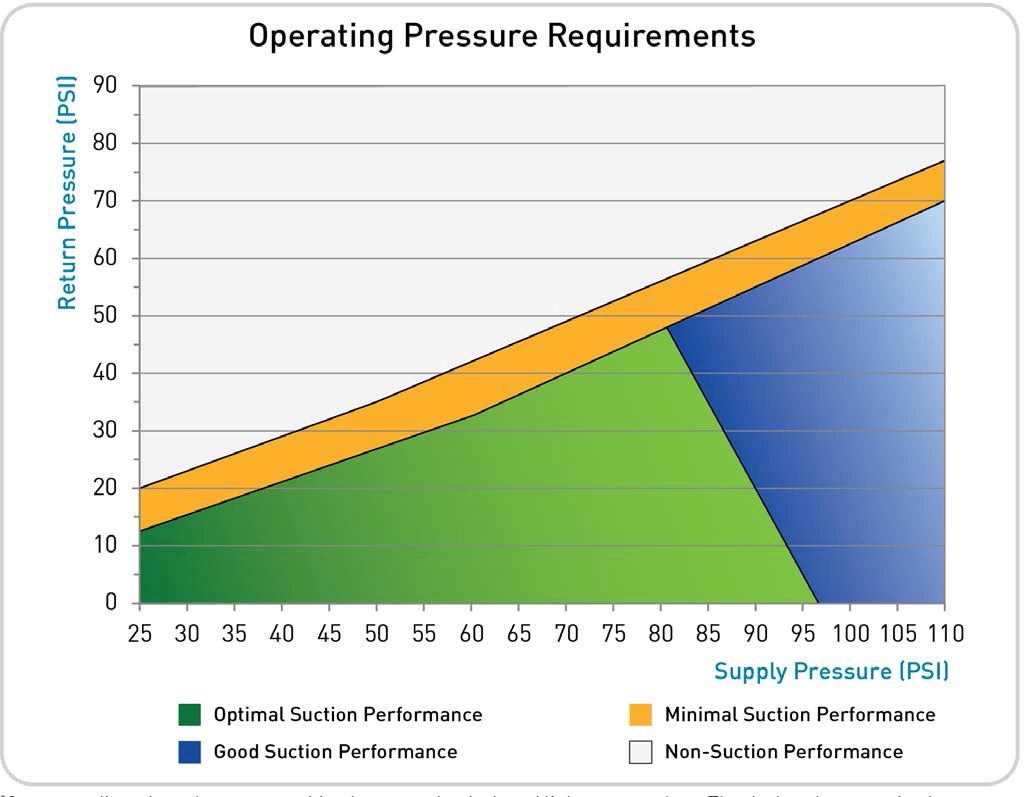

eVac Module Operating Pressures

| WeldSaver6 eVac | |

|---|---|

| Control Interface Options | EtherNet/IP™ • PROFINET® |

| User Interface | Browser-based UI • Local display with keypad |

| Flow Range | 6.0 - 50 LPM / 1.5 - 13 GPM |

| Temperature Range | 4.0 - 110 °C / 39 - 230 °F |

| Connection Options | G 3/4” (BSPP) • 3/4” NPT |

| Coolant Supply Pressure | 83 - 689 kPa / 12 - 100 psig |

| Coolant Return Pressure | 52 - 689 kPa / 7.5 - 100 psig |

| Differential Pressure | 14 - 620 kPa / 2.0 - 90 psig |

| Compressed Air Pressure | 300 - 800 kPa / 43.5-116 psig |

| Low Flow Response | < 0.2 sec. |

| Reset / Override Response | < 1.0 sec. |

| Leak Detection Response | 0.3 - 1.0 sec. depending on response time selection and back pressure |

| Leak Sensitivity | Able to detect a loss of flow continuity from 1-20 balanced parallel flow paths |

| Accuracy | ± 3% of full scale |

| Repeatability | ± 1% of full scale from 0.1 to 1.0 x full scale |

| Operating Environment | Indoor use only |

| Ambient Temperature | 4.0 - 50 °C / 39 - 122 °F |

| Max. Relative Humidity | 80% |

| Enclosure Protection | IP66 / NEMA 4X |