Our Solutions

- Bin-picking applications

- Magnetic Handling Applications

- Modular EOAT

- Destacking/Thin Sheet Application

- Collaborative robots

Brands

Our product range

Support & Services

Our Solutions

- Packaging Machines Applications

- Medical/Parmaceutical Equipment

- Hose and Cable Reel Applications

- Multimedia and Entertainement Equipment

- General Industry Equipment

- Test Benches Applications

- Harsh Environment Applications

Brands

Our Solutions

- Welding Process Applications

- Handling Applications

- Riveting/Gluing applications

- Vision or inspection applications

- Stamping line applications

Assemblies

Support & Services

Components

End-of-Arm Tooling Solutions

Products for all your applications

Solutions for:

Bin picking

With the magnetic gripping solutions offered by P.E.S, bin picking has never been easier. Our technology allows repeated and fast switching and offers a very interesting power/compactness ratio for these applications. Objects contained in bulk in bins can be picked by your robot using a vision system or completely randomly and then introduced into a production line.

Handling

Our switchable magnets, based on permanent magnet technology, are very energy efficient and safe. Compact and lightweight, with mounting interfaces that comply with industrial standards, they can be easily integrated into your EOAT of all types. The possibility of adding magnetic jaws will open up new ways ofdesign for your end-of-arm tooling.

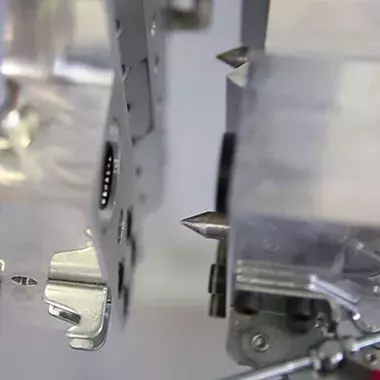

Modular grippers

Increased flexibility and adaptability thanks to our automated or manual quick-change interfaces. With multiple levels of possible modularity, you will be able to adapt your production tools as you wish between each production batch.

Destacking

Destacking is often a delicate task that requires several devices: sheet fanners, suction cups for handling, double sheet metal detectors, etc. Our electrically controlled magnetic solutions integrate all the functionalities from destacking to safe handling and detection. Indeed, thanks to their variable field control, these magnets can be adapted to destack any thickness of sheet metal and carry out the handling task that follows, their magnetic flux sensor will ensure you have the right grip at all times.

Cobots

Our magnetic gripping range is particularly suitable for collaborative applications, safe and without moving parts (outside the tool), our low load magnets will fit perfectly this kind of application due to their compactness and low energy requirements.