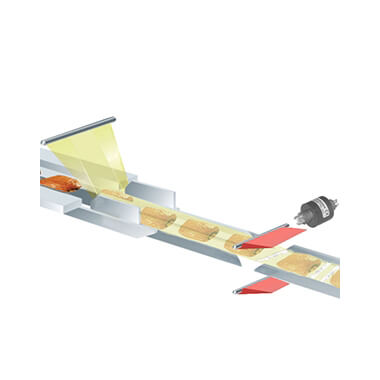

Transferring Power and Temperature Sensor Signals to Cut and Seal Plastic Films

Continuous flow is a key feature of a packaging machine, to save space and keep mechanical structures as simple as possible while meeting high production rates rotating movement are widely used.

This is the case of the flow pack machines family that aims to cut and seal plastic packaging at the end of the production line.

To achieve that, a rotating blade is used. It is made up of an electric resistance that heats the sealing blade and the temperature is monitored by a thermocouple temperature sensor embedded in the blade. A slip ring is then used in order to feed the electrical resistance and retrieve thermocouple signals between the rotating blade and the computer side.

In this case, a special design of slip ring with mounted faston terminals has been developed, it allows easy maintenance while offering the best contact quality for thermocouple reading that can be affected by welds in standardSlip ring.

Electrical Features

- Power up to 20A/400V

- Thermocouples or other sensors signals

- Faston terminals avoiding welds to connect thermocouples

Mechanical Features

- Low friction torque

- Compact size and low weigth

- Up to 400rpm

Interesting options

- IP65 option

- Combination with pressurized air rotary union

Advantages

- Long life-time without maintenance (about 100M rotation)

- Faston terminals for easy maintenance

- Compact and made up of standard components

Benefits

- Low maintenance cost

- Reliable Operation between Failure

- Cost-effective replacement part

Facts & Figures

- With a medium speed of 200rpmSlip ring for flow pack machines can operate nearly 1 year without being replaced

- Power signals and sensors signals (thermocouples) can be embedded in the same slip ring