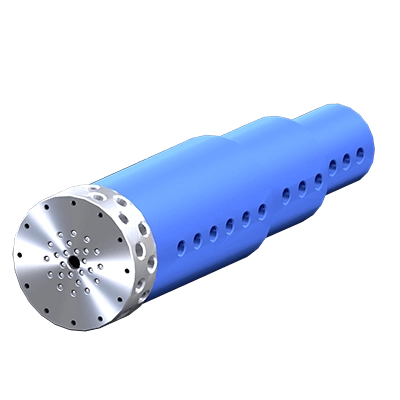

Rotary Union | 24 passages | LT(M) 21241

The perfect solution for vacuum or pneumatic applications

The LTM Series rotary unions are small and lightweight available in 2, 4, 8, 12 & 24 passage versions. They are the perfect solution for vacuum or pneumatic applications.

The LTM Series rotary unions feature all-aluminum construction and low-torque seals. They are suitable with a many industrial applications where pressure and/or vacuum is needed. They can be combined with slip rings thanks to the range of mounting accessories and their hollow shaft that allows pass-through elecrical wiring.

Advantages

- Multipurpose solution for air and/or vacuum

- Easy integration

- Multi-channel and competitive cost

- Can be easily combined with electrical slip rings

Benefits

- Avoid the need of complex piping arrangements

- Increased machinery performances

- Paiping maintenance mitigated