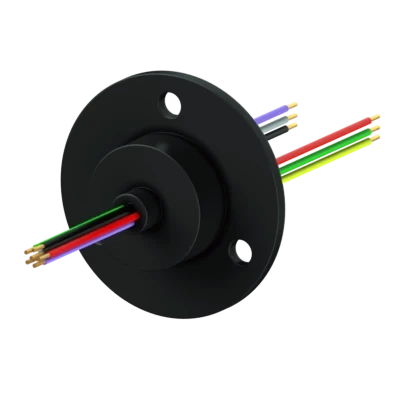

Slip Ring | 18 circuits | SVTS A 01-S-X-00/18

Compact, cost-effective, O.D. 12 mm, 3 to 18 circuits

Slip ring specially suited to transmit critical signals, such as hi frequency and data rate, low current and voltages (strain gauges, thermocouples, measuring equipment, etc.)

These units are available in many standard configurations from 2 to 18 circuits. Due to their small ring diameter, the SVTS A 01 series grants low peripheral speed between bushes and rings, as well as reduced dynamic imbalance that means very low wear and long life. Thanks to the small ring diameter they can transmit high frequency signals such as video.

Advantages

- Ideal for video, high frequency signals

- High data rate

- Gold alloy rings and brushes

- Low friction torque

- High lifetime and reliability

- Combinable with fluidic rotary joints and FORJ

- Compliant to CE and ROHS

Benefits

- Optimal signal transmission (gold-gold technology)

- Cost-effective