Our Solutions

- Bin-picking applications

- Magnetic Handling Applications

- Modular EOAT

- Destacking/Thin Sheet Application

- Collaborative robots

Brands

Our product range

Support & Services

Our Solutions

- Packaging Machines Applications

- Medical/Parmaceutical Equipment

- Hose and Cable Reel Applications

- Multimedia and Entertainement Equipment

- General Industry Equipment

- Test Benches Applications

- Harsh Environment Applications

Brands

Our Solutions

- Welding Process Applications

- Handling Applications

- Riveting/Gluing applications

- Vision or inspection applications

- Stamping line applications

Assemblies

Support & Services

Components

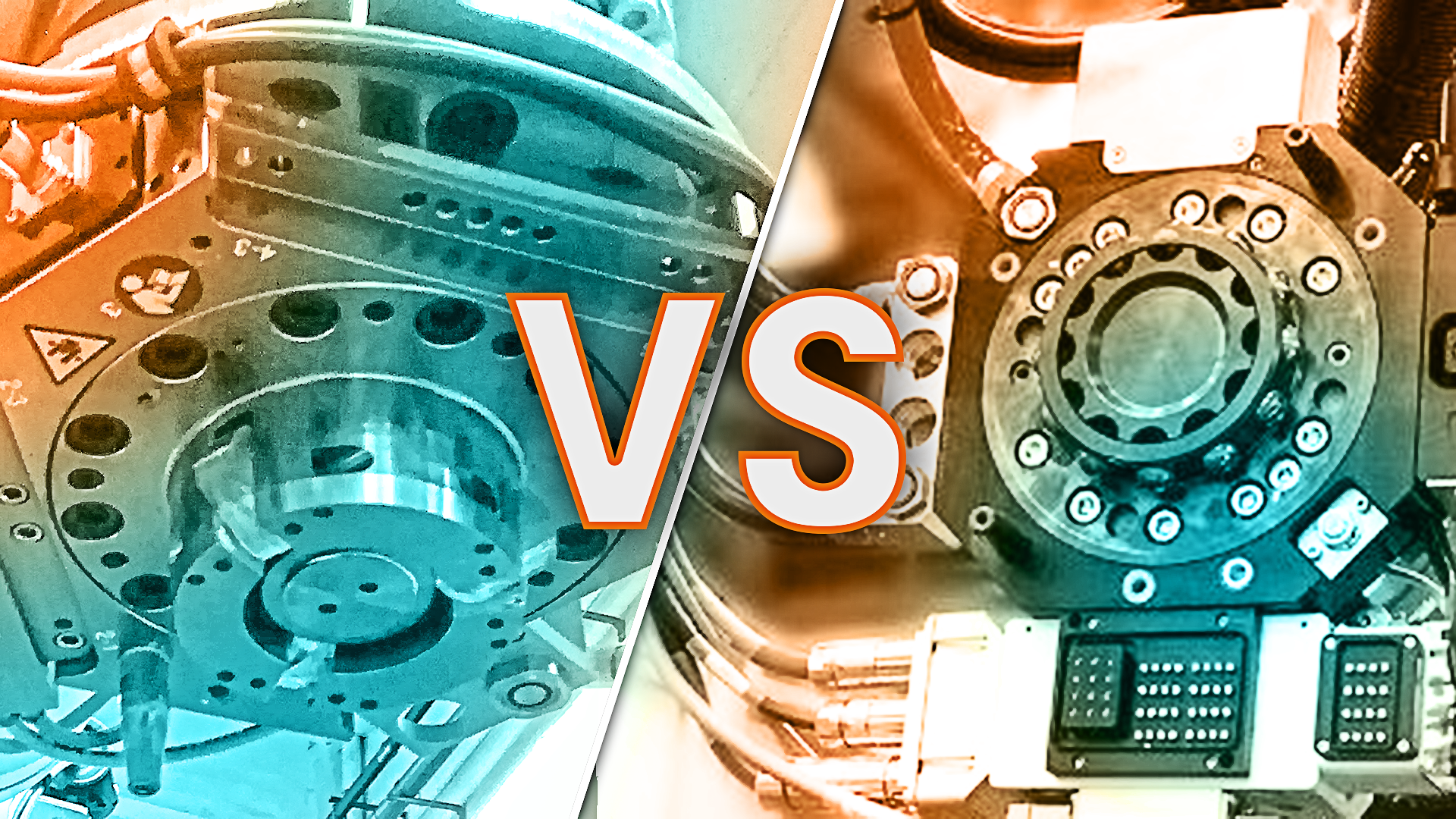

Cam-Locking vs Ball-Locking Robotic Tool Changers: Which Technology Is Best for Your Industrial Robots?

In the world of robotic tool changers, two major locking technologies coexist:

- Cam-locking tool changers (such as the Epsilon XCHANGE™ line from Effecto / Applied Robotics, distributed by PES),

- Ball-locking tool changers (“ball & collet” systems), used by many manufacturers.

The choice of locking mechanism has a direct impact on safety, robot cell uptime, maintenance, and the overall total cost of ownership (TCO). This comparative article provides clear, structured insights to help manufacturers in Belgium, France, and across Europe choose the most suitable solution for their robotic applications.

1. Understanding the Role of the Locking Mechanism in a Robotic Tool Changer

A robotic tool changer consists of a master plate on the robot side and a tool plate on the end-effector side. The locking mechanism ensures:

- Secure engagement between both plates,

- Transmission of utilities (air, fluids, signals, power),

- Positional repeatability of the tool, even after millions of cycles.

At Product Engineering Services (PES), tool changers are engineered with robust cam systems designed to withstand high loads and remain reliable even in demanding industrial environments.

2. Cam-Locking Tool Changers (Effecto / Applied Robotics via PES)

Cam-locking tool changers, such as the Epsilon series from Effecto (Applied Robotics), use a cam-and-dowel locking mechanism.

2.1 How Cam-Locking Works

- Cams driven by a double-acting pneumatic actuator engage onto dowels or dedicated surfaces.

- The locking is positive: the cams mechanically envelop the dowel, limiting play and preventing unwanted disengagement.

- The cam profile is self-compensating for wear, meaning the system “wears in” rather than “wears out,” maintaining high repeatability over time.

2.2 Key Advantages of Cam-Locking Tool Changers

High robustness & heavy-load capability

- Load capacities ranging from a few kilograms to more than 2,300 kg for heavy-duty models (e.g., Epsilon ES315).

- Excellent performance under high moment loads and accelerations, ideal for modern 6-axis industrial robots.

Superior process safety

- Linear cam engagement with a wide surface contact area.

- Greatly reduced risk of free-wheel (tool spinning freely) in the event of a dowel failure compared to some ball-locking designs.

- Positive locking and unlocking: pneumatic control is fully managed in both directions.

Maintenance & total cost of ownership

- The system wears in, maintaining stable mechanical performance throughout its life.

- Maintenance is simple: visual inspection, checking dowels and centering bushings, periodic cam lubrication.

- Lifetime warranty on the locking mechanism for the Epsilon range, reflecting high reliability.

Performance in harsh environments

- Self-cleaning design suitable for dusty environments, welding, chips, and heavy contamination.

- Less prone to jamming compared to ball-based systems when exposed to particles.

In summary, cam-locking tool changers such as Epsilon XCHANGE™, integrated and distributed by PES, are ideal for demanding industrial applications, heavy loads, or harsh environments (welding, stamping, sheet-metal handling, large tooling).

3. Ball-Locking Tool Changers (Ball & Collet Systems)

Ball-locking tool changers use a collet-type mechanism where steel balls seat into spherical cavities on the tool plate.

3.1 How Ball-Locking Works

- Balls are forced into grooves or cavities using a conical or bi-conical piston.

- This point-contact interface provides both centering and locking.

- Unlocking is achieved by retracting the piston or removing pressure.

3.2 Key Advantages of Ball-Locking Tool Changers

Widely adopted technology

- Used by many manufacturers, making it easy to source and compare alternatives.

High precision and repeatability

- Very good positional repeatability: some models reach micrometer-level accuracy across hundreds of thousands of cycles.

Compact and lightweight

- Often extremely compact and light, ideal for small to medium-payload robots.

3.3 Limitations and Risks of Ball-Locking Systems

Sensitivity to contamination

- Balls may jam in the collet when exposed to dust, welding spatter, chips, or other contaminants, making unlocking unreliable.

Safety concerns in case of component failure

- Certain designs may experience free-wheel if a dowel or internal guide component breaks, presenting risks for operators and equipment.

Concentrated wear

- Point-contact wear on balls and grooves may require more frequent reconditioning of the collet, grooves, and ball set.

4. Side-by-Side Comparison: Cam vs Ball Locking

4.1 Comparison Table

| Criteria | Cam-Locking Tool Changer (Effecto / PES) | Ball-Locking Tool Changer (Generic) |

|---|---|---|

| Locking principle | Cams + dowels, linear engagement, surface contact | Balls + collet, point-contact in grooves |

| Robustness / heavy loads | Excellent, with ranges above 2,300 kg | Good but varies widely across manufacturers |

| Wear behavior | System “wears in,” maintains precision | Concentrated wear on balls and grooves |

| Contamination resistance | Self-cleaning, ideal for harsh, dirty environments | Much more sensitive to jamming |

| Mechanical safety | Positive locking, no free-wheel risk (depending on design) | Potential free-wheel if a guiding element fails |

| Maintenance | Simple checks + lubrication; low TCO; lifetime warranty | More frequent reconditioning required |

| Mechanical integration | High-strength aluminium body, wide utilities offering | Very wide range of sizes among many brands |

| Best suited for… | Medium to heavy loads, harsh environments, critical processes | Light to medium robots, clean environments, budget-focused projects |

5. Which Tool Changer Should You Choose?

5.1 When to choose a cam-locking tool changer (Effecto / Applied Robotics via PES)

A cam-locking tool changer is strongly recommended when:

- you handle high loads or high moments (sheet metal handling, heavy tooling, assembly jigs),

- your environment is harsh or contaminated (welding, spatter, dust, oils, chips),

- uptime of your robotic cell is critical and unplanned stops must be minimized,

- you aim for a low total cost of ownership with minimal maintenance and extremely long system life.

In this case, the Epsilon and Sigma ranges offered by PES provide a very robust solution, with local support for sizing, integration, and reconditioning.

5.2 When a ball-locking changer is sufficient

A ball-locking tool changer is suitable when:

- robot payloads are moderate and involve small to medium-sized robots,

- your environment is clean (electronics assembly, small parts handling, vision, laboratory),

- you require maximum compactness and a lower initial investment.

In these cases, a good-quality ball-locking changer performs well, provided the environment and maintenance are controlled.

6. Conclusion: Why PES Promotes Effecto Cam-Locking Tool Changers

As an integrator and distributor, PES highlights the cam-locking tool changers from Effecto / Applied Robotics for their:

- long-term mechanical reliability,

- resistance to harsh environments,

- enhanced safety for operators and equipment,

- reduced total cost of ownership thanks to simplified maintenance and self-compensating wear.

Ball-locking tool changers remain a solid alternative for clean environments, low loads, and budget-sensitive applications. However, for intensive manufacturing, heavy-duty operations, or critical industrial processes, cam-locking offers superior safety and robustness—especially with the Epsilon XCHANGE™ technology available through PES.

FAQ: Common Questions about Cam-Locking vs Ball-Locking Tool Changers

What is the main advantage of a cam-locking robotic tool changer?

The main advantage is mechanical robustness and reliability in harsh industrial environments. The positive-locking cam mechanism delivers high safety, high repeatability, and long-term durability, even in heavy-load applications.

When should I choose a ball-locking tool changer?

Ball-locking designs are appropriate for light to medium robots operating in clean environments, where compactness and low initial cost matter more than extreme durability.

Are cam-locking tool changers compatible with most industrial robots?

Yes. The Epsilon XCHANGE™ range from Effecto / Applied Robotics, distributed by PES, supports many ISO interfaces and integrates with most major robot brands used in Belgium, France, and throughout Europe.

What maintenance does a cam-locking changer require?

Maintenance is limited to visual inspection, checking dowels and centering bushings, and periodic cam lubrication. These simple steps keep performance stable and the TCO very low.

How can I know whether my application needs cam-locking or ball-locking?

It depends on payload, moment loads, environmental conditions, and required uptime. If unsure, you can contact PES for a personalized assessment and neutral recommendation.