Robot Manual Tool Changers | Medium Payload | SHS125

Optimize your processes with the SHS050: the fast and reliable tool changer for uninterrupted production.

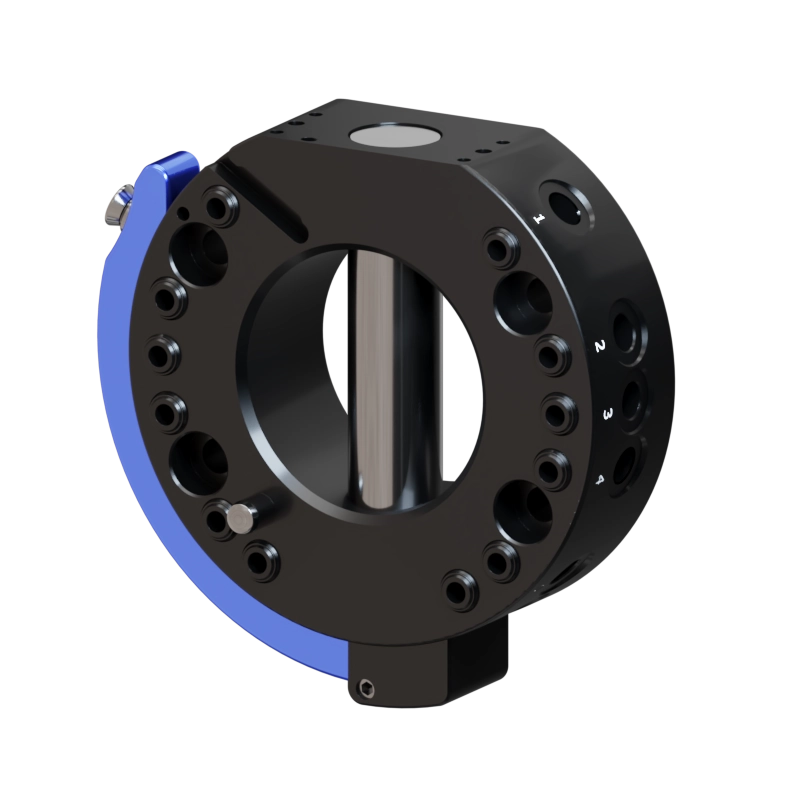

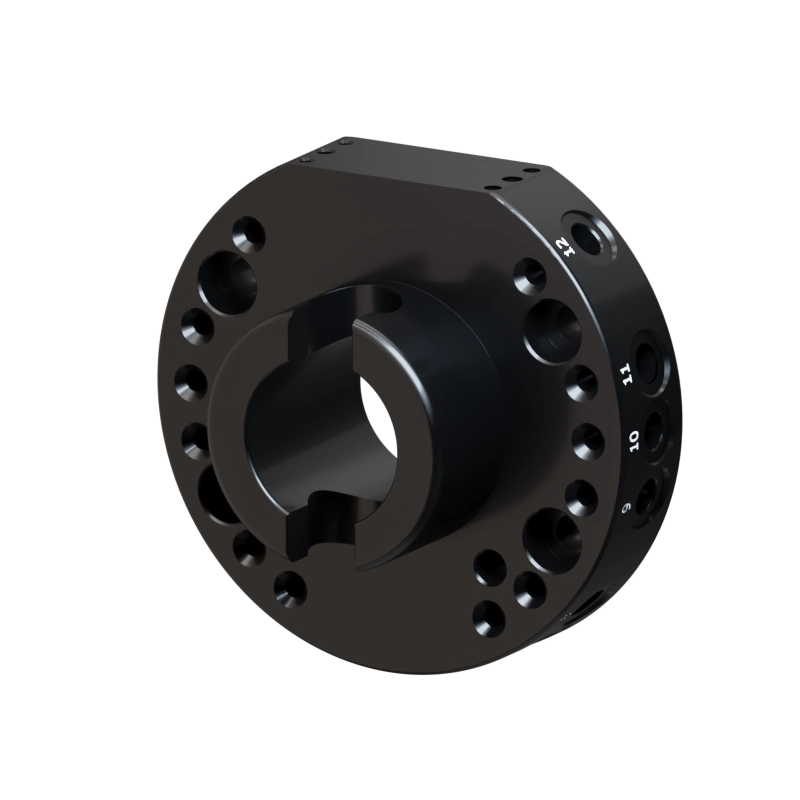

The SHS Connector is equipped with integrated pneumatic feedthroughs, with electrical feedthroughs being optional. The Connector consists of a cylindrical bolt which locks the upper and lower assemblies. Closing the lever to lock, cinches the two assemblies together. A centering disc can be installed on both the upper assembly (robot side) and lower assembly (tool side) and ensures that the tools are correctly aligned with the robot arm.

Advantages

- Withstands high loads with low dead weight

- Can be released and closed with one handle

- During locking, the lower assembly is pulled around the locking stroke

- Interface according to DIN EN ISO 9409-1

Benefits

- Does not require a deep review of the echanical structure to be integrated.

- Cost savings through reduced maintenance downtime.

- Improved equipment versatility and upgradability and then extended productivity.

- Mitigate the need of specifically designed mounting interfaces