Robot Manual Tool Changers | Medium Payload | SWS160

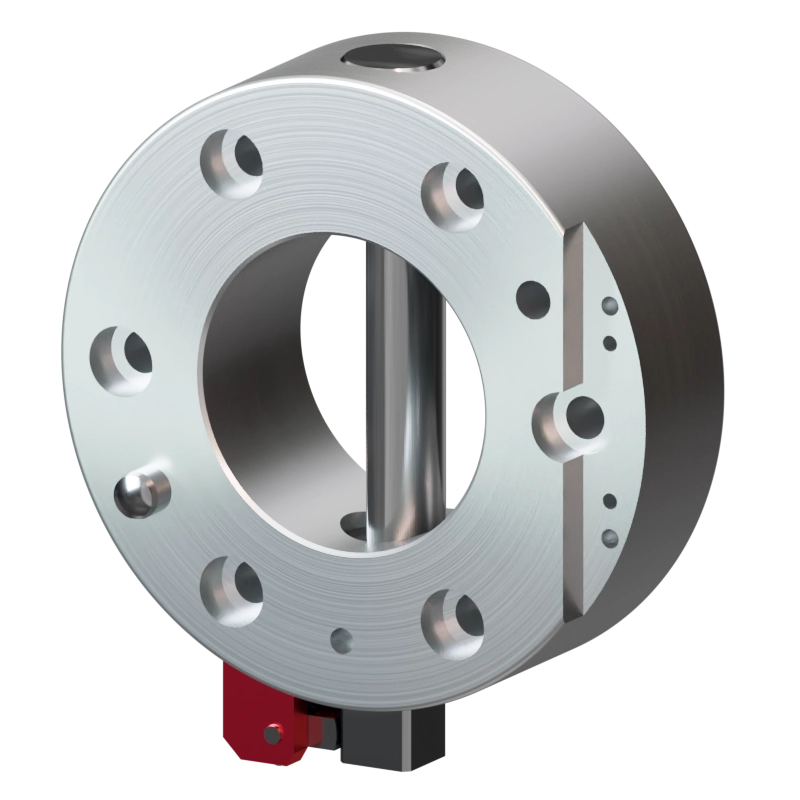

The SWS series allows accurate tool changing operations with increased safety

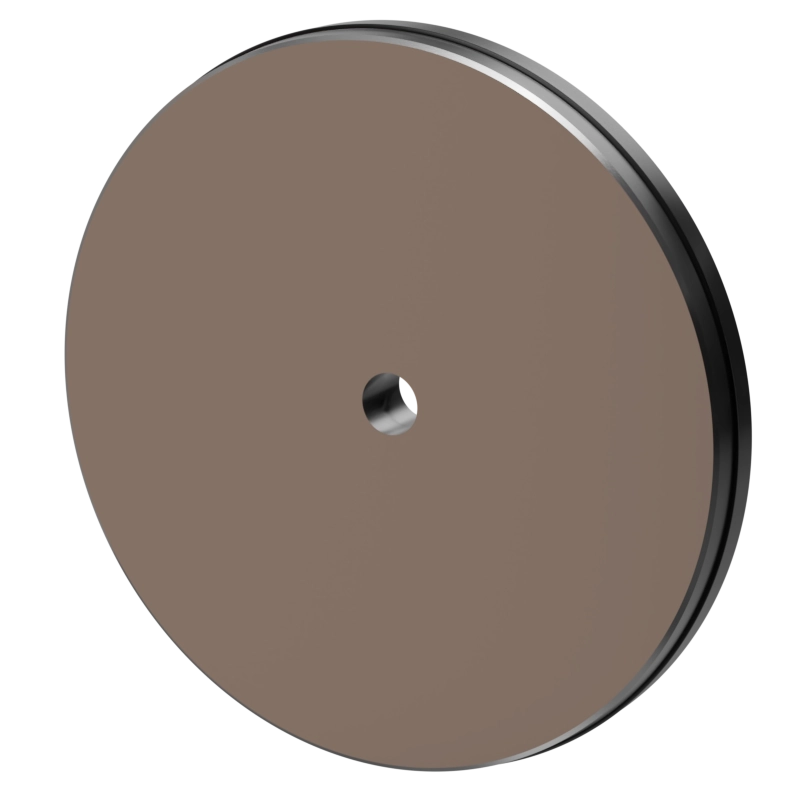

The SWS Connector is our power pack for applications with increased force and torque loads. The semi-cylindrical bolt accurately joins the upper and lower assembly without play. A centering disc can be installed on both the upper assembly (robot side) and lower assembly (tool side) of the robot and ensures that the tools are correctly aligned with the robot arm.

Advantages

- Withstands high loads with low dead weight

- Can be released and closed with one handle

- During locking, the lower assembly is pulled around the locking stroke

- Interface according to DIN EN ISO 9409-1

Benefits

- Does not require a deep review of the echanical structure to be integrated.

- Cost savings through reduced maintenance downtime.

- Improved equipment versatility and upgradability and then extended productivity.

- Mitigate the need of specifically designed mounting interfaces