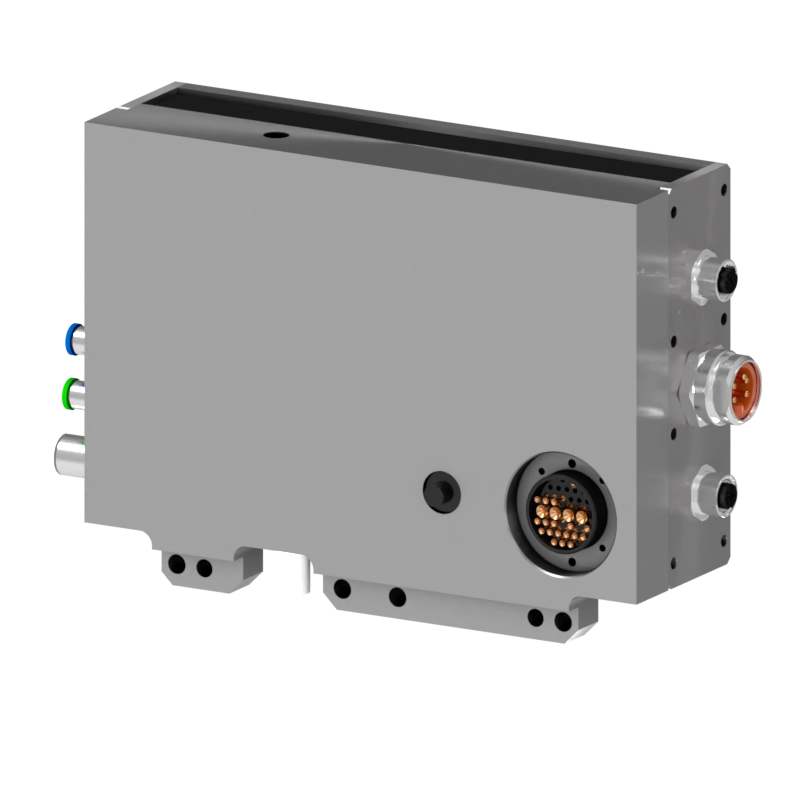

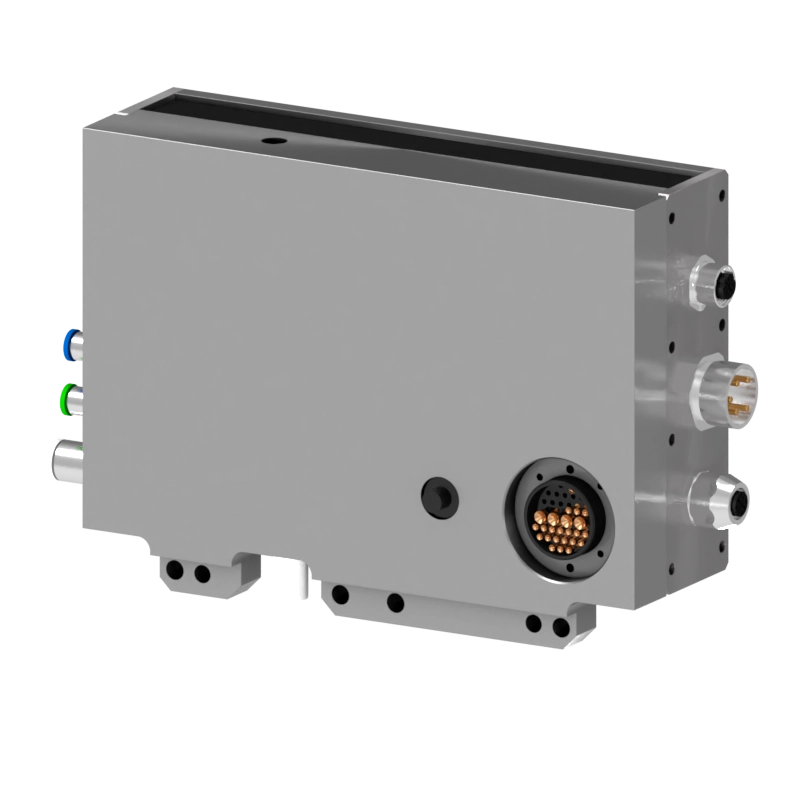

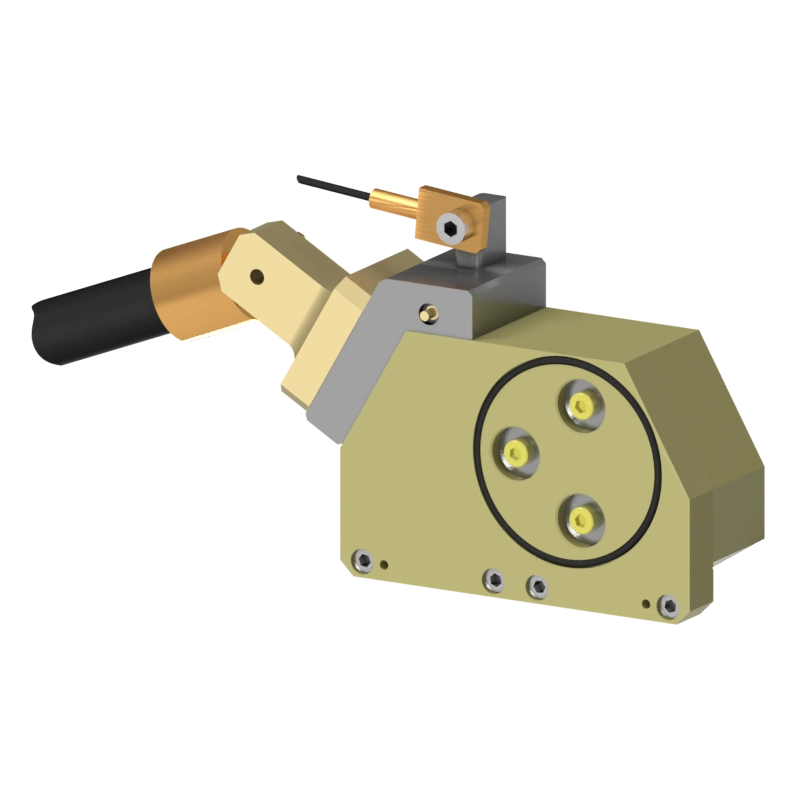

Robot Tool Changers | Heavy Payload | Sigma 8.1

Sigma the foolproof tool changer range

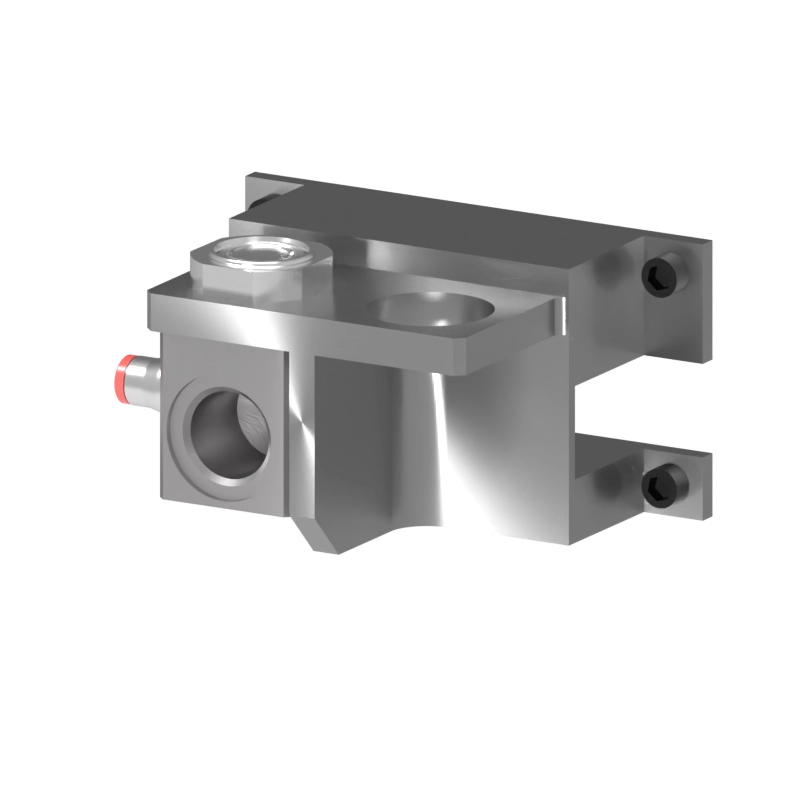

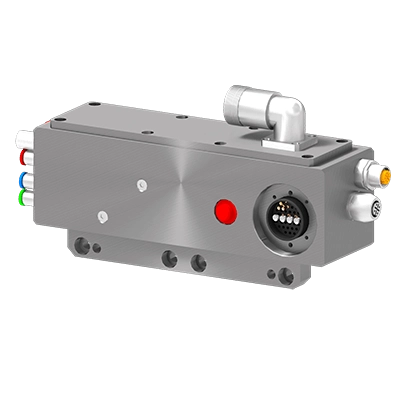

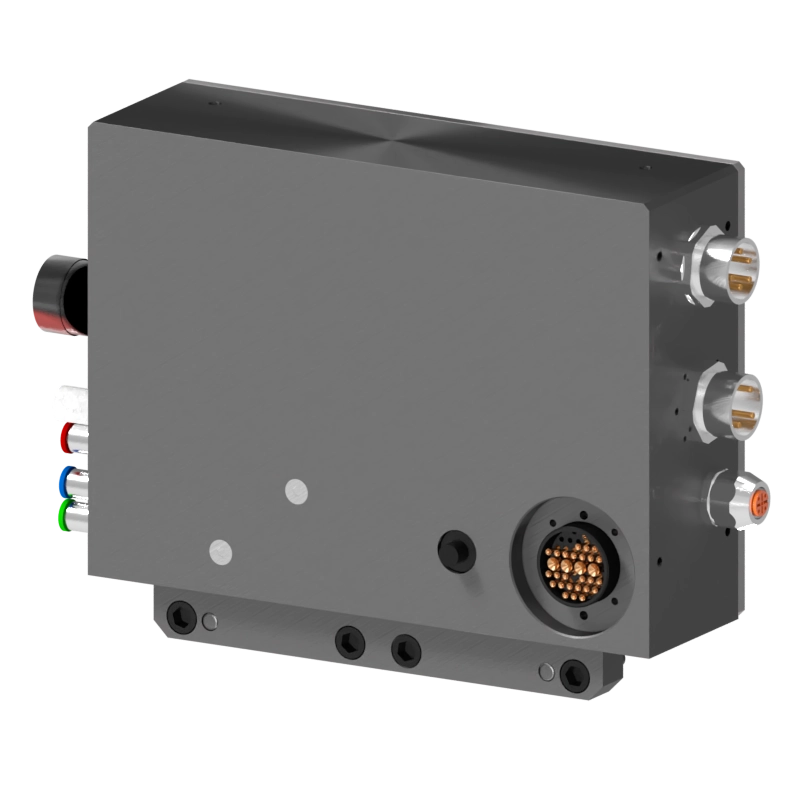

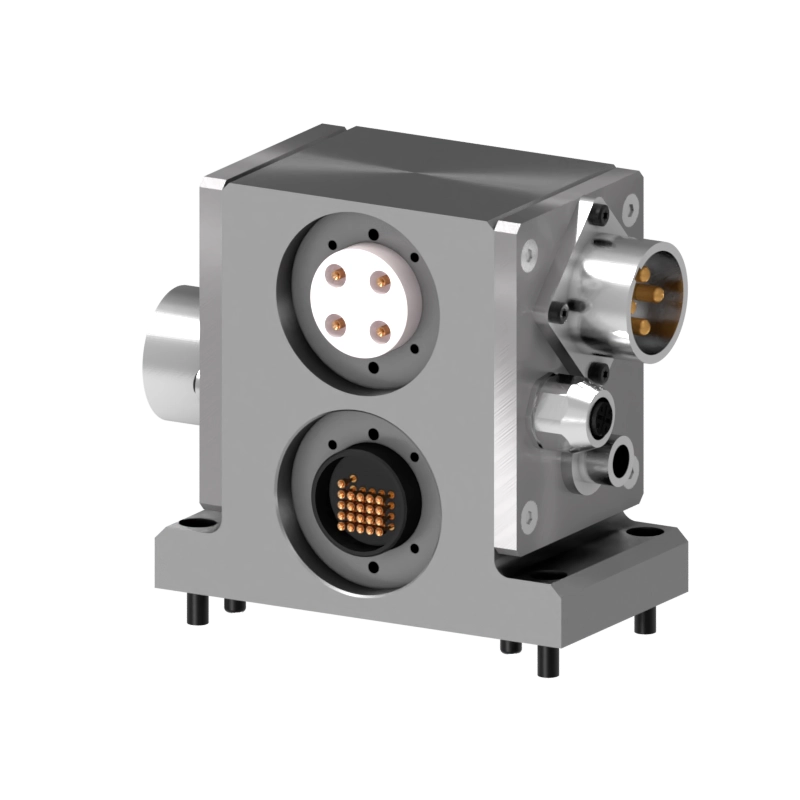

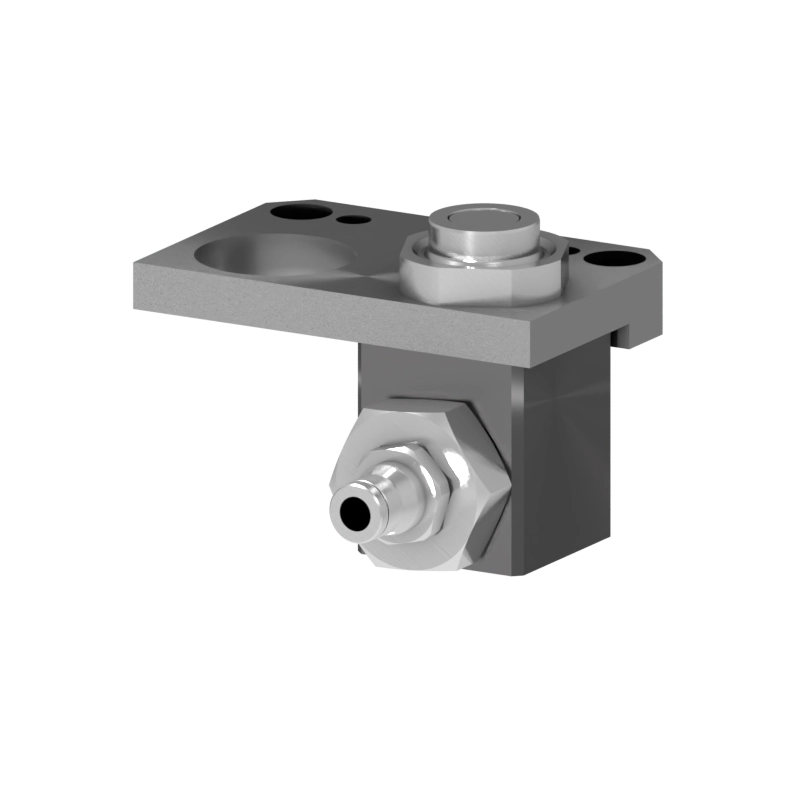

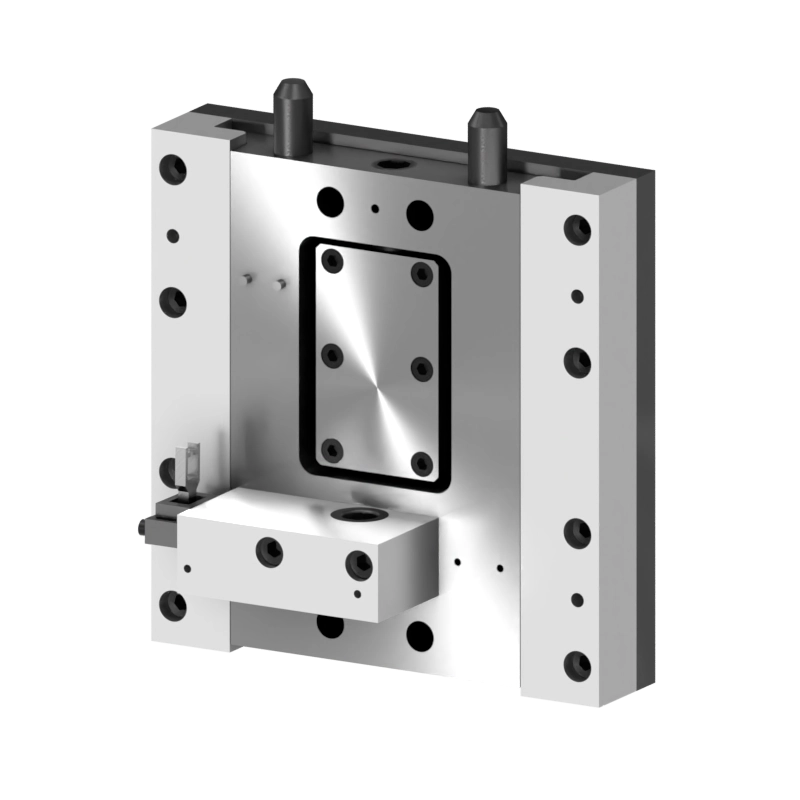

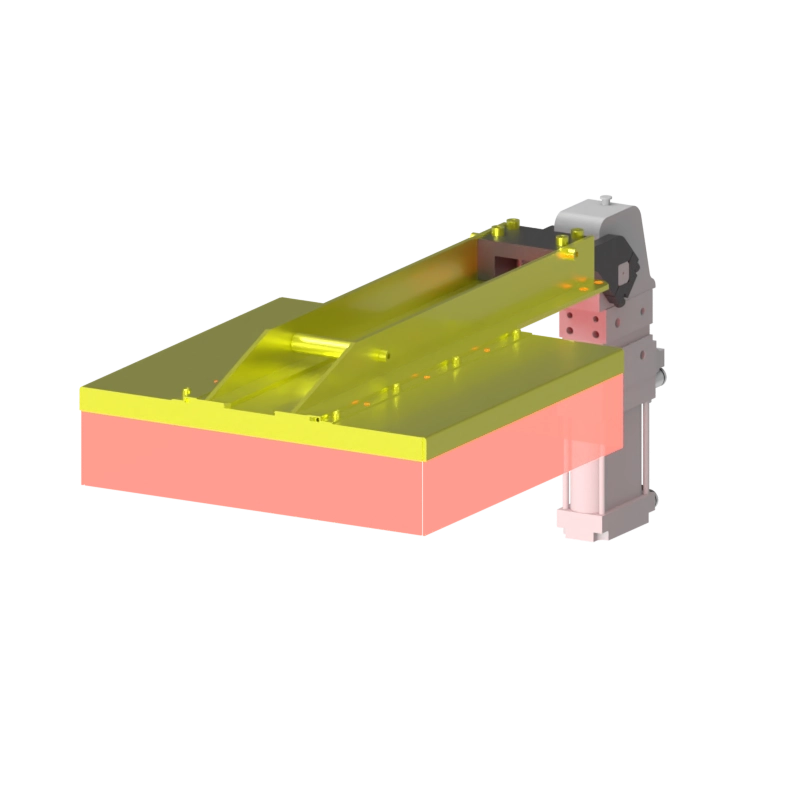

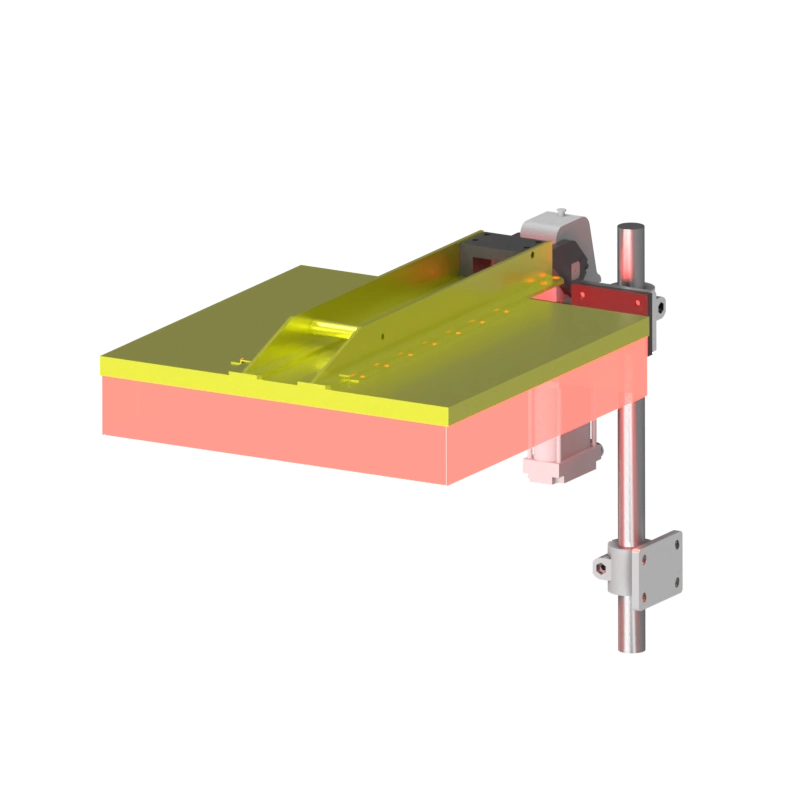

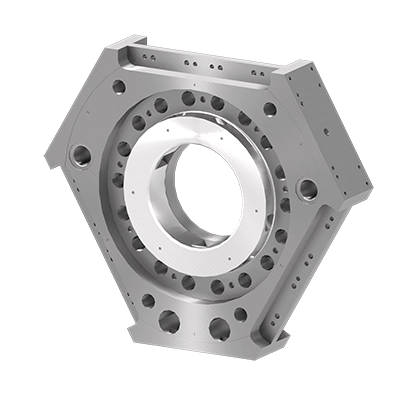

Sigma 8.1 tool changers offer a higher payload capacity up to 800kg. Their low profile design reduces inertial forces.

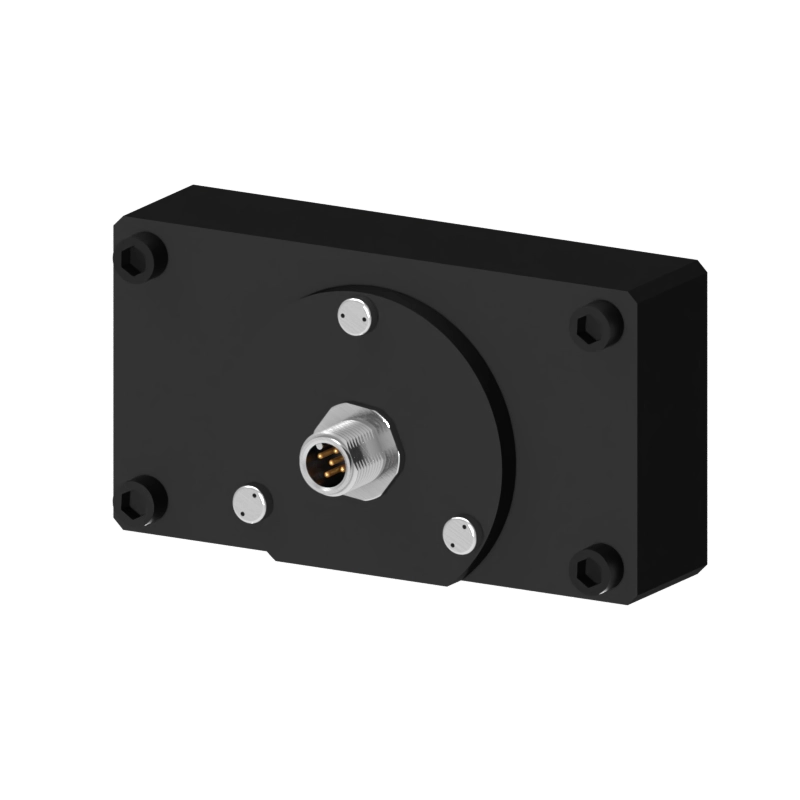

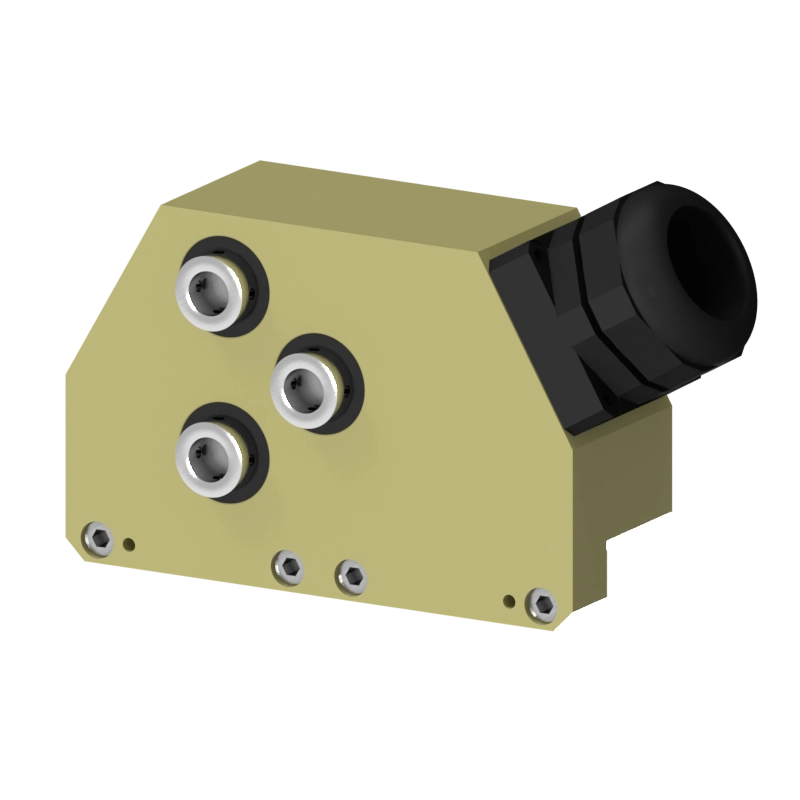

Heavy Payload Tool Changers are gathered within Sigma Series. They allow handling payloads from 350kg till 800kg and are particularly suited for various applications such as spot welding, material handling, machine loading/unloading, mold changing, docking systems, pallet coupling systems, pick and place operations, press transfer.

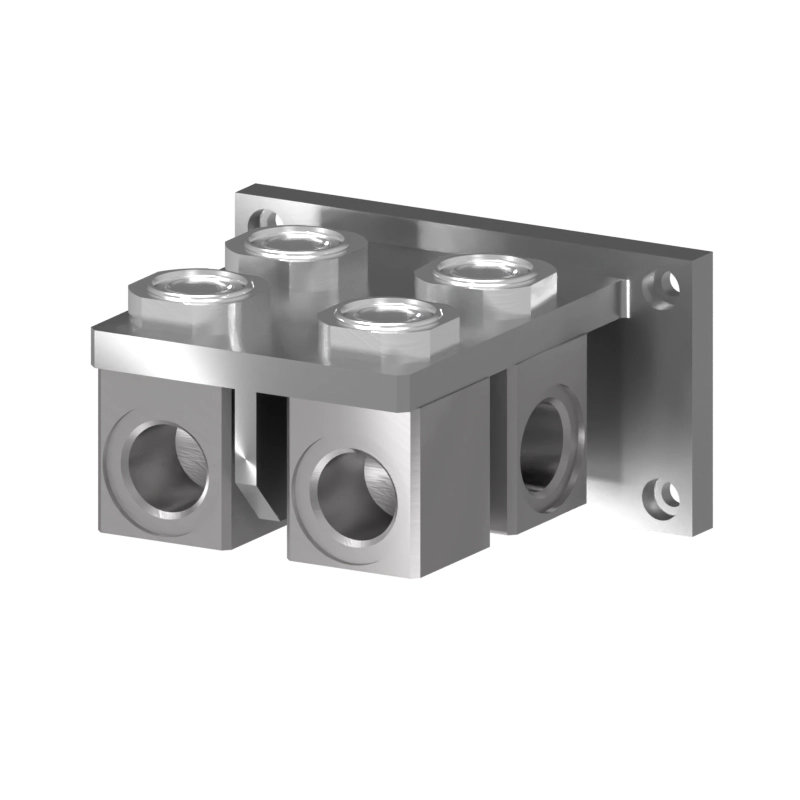

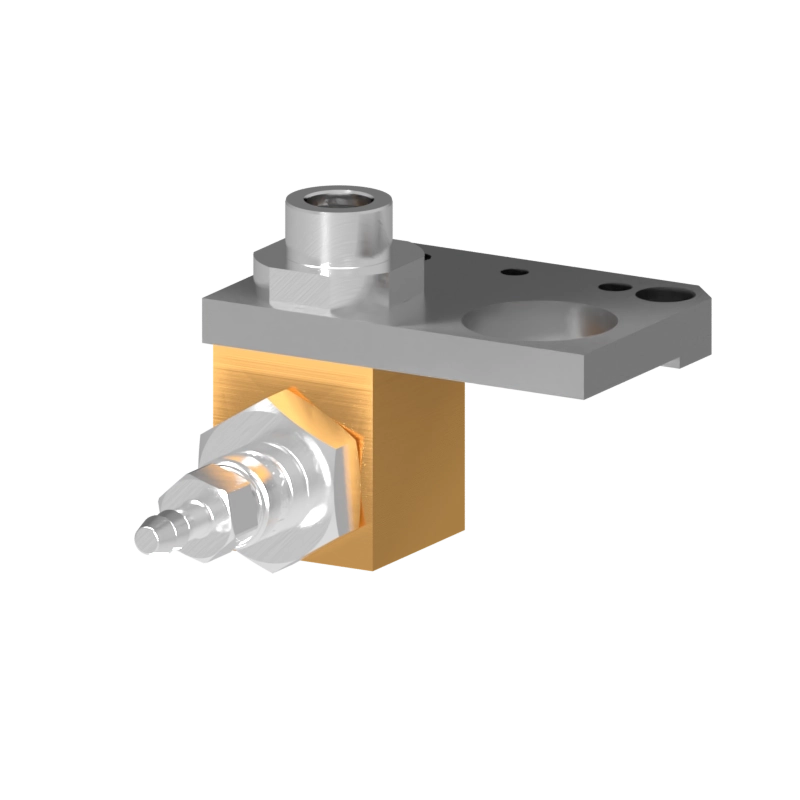

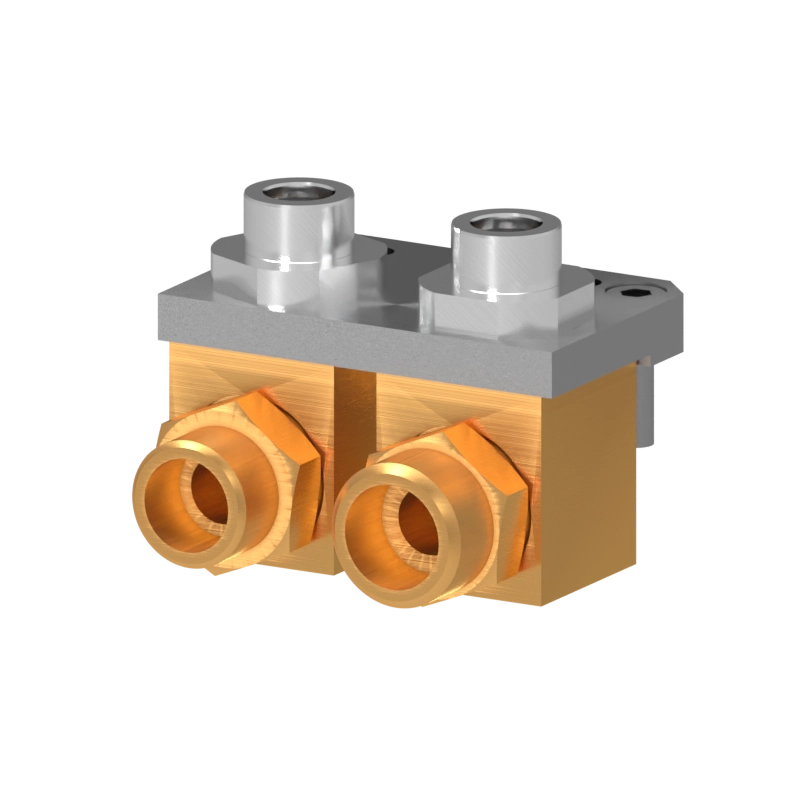

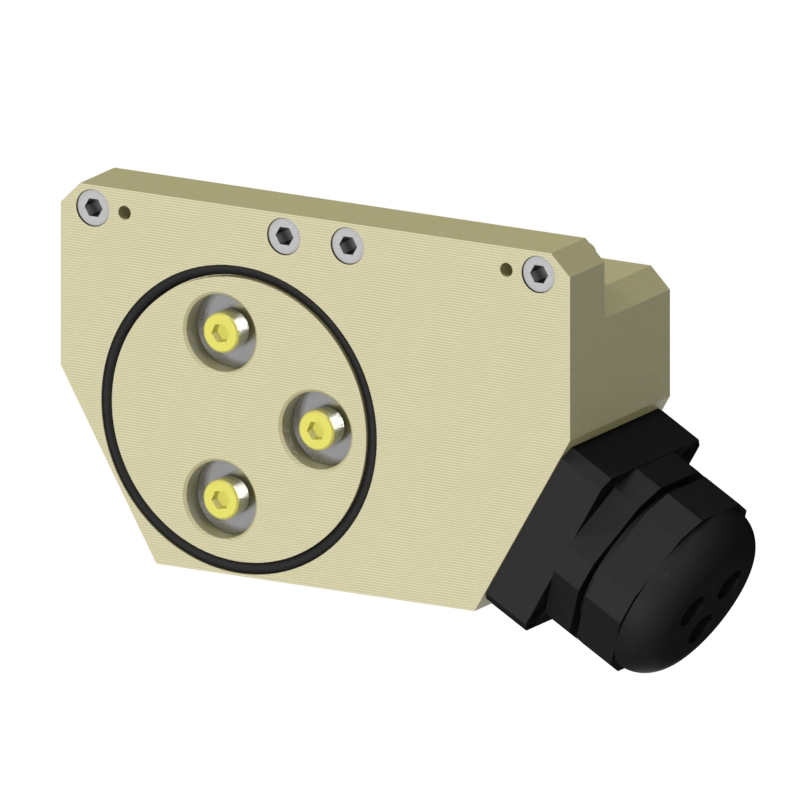

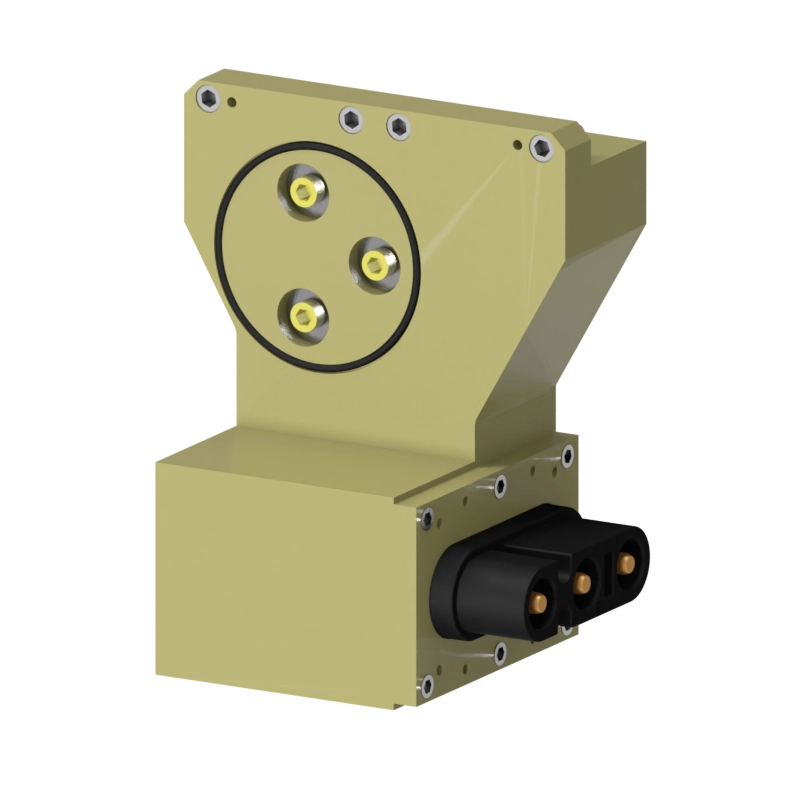

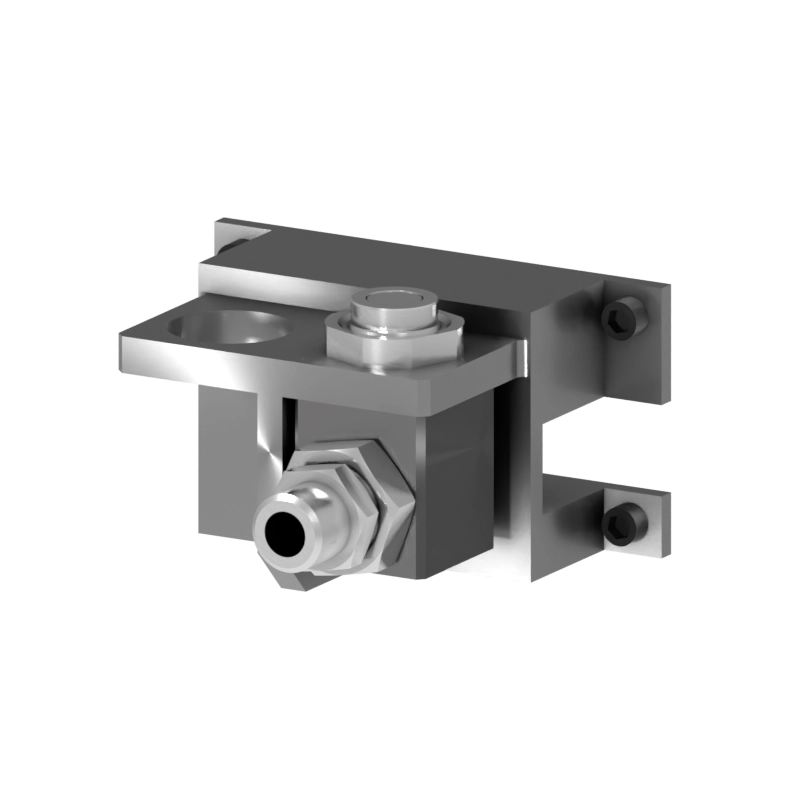

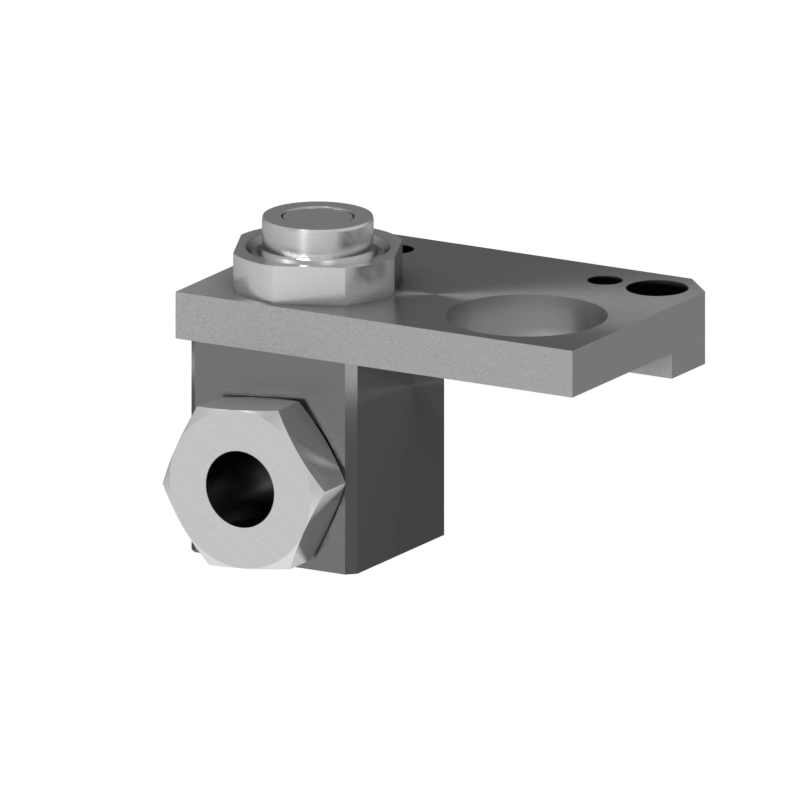

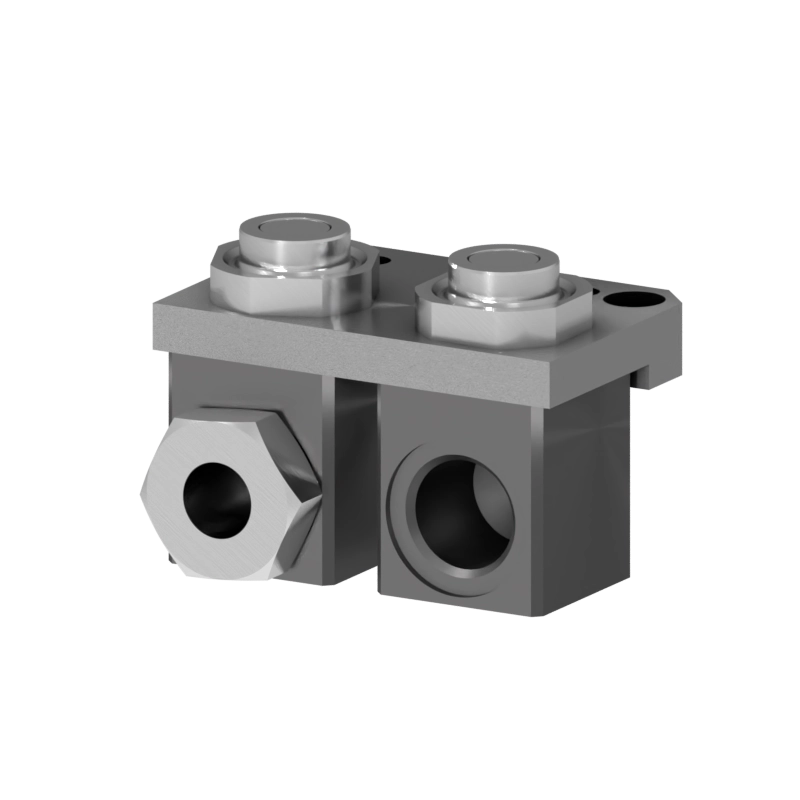

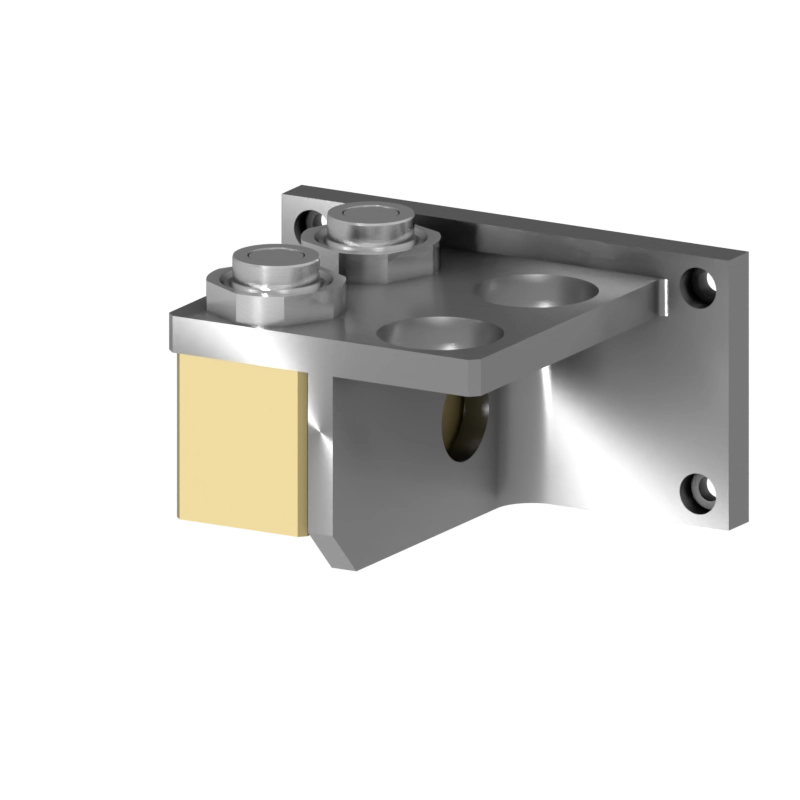

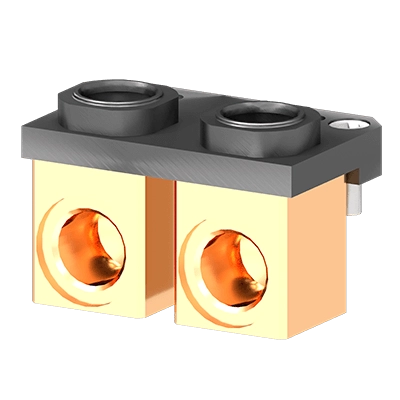

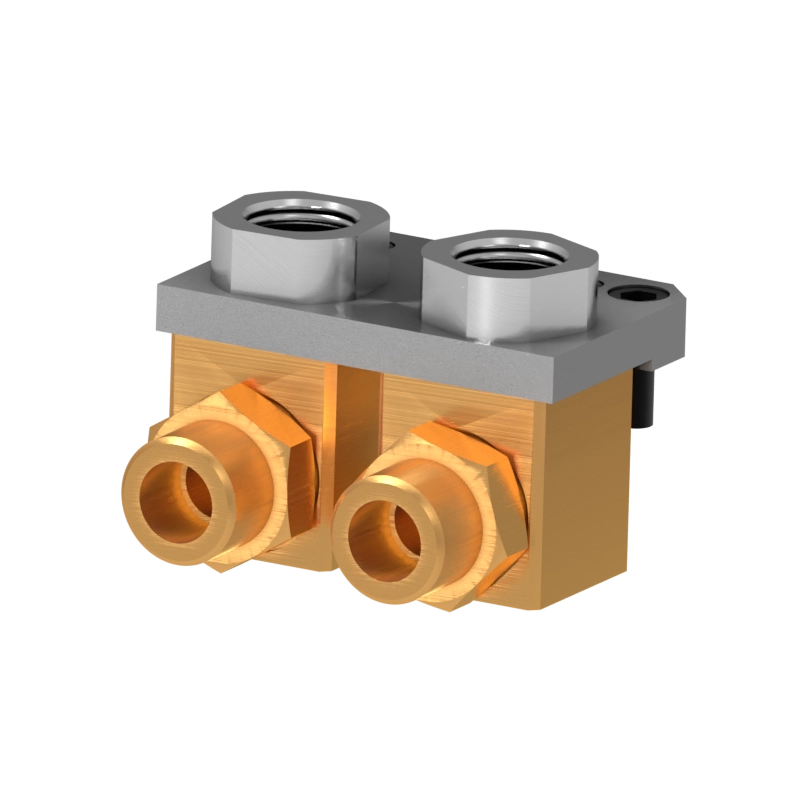

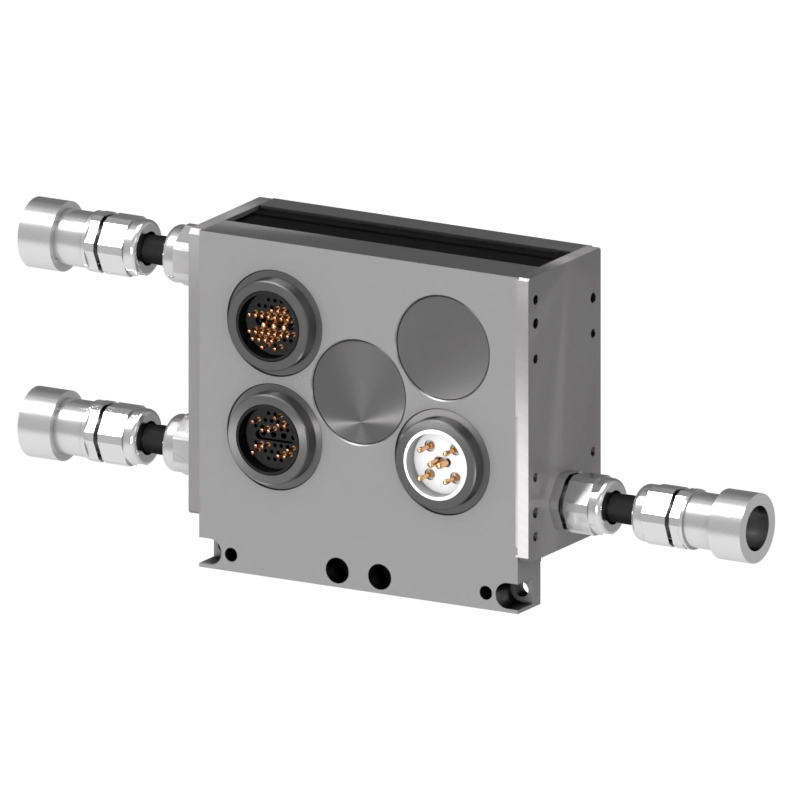

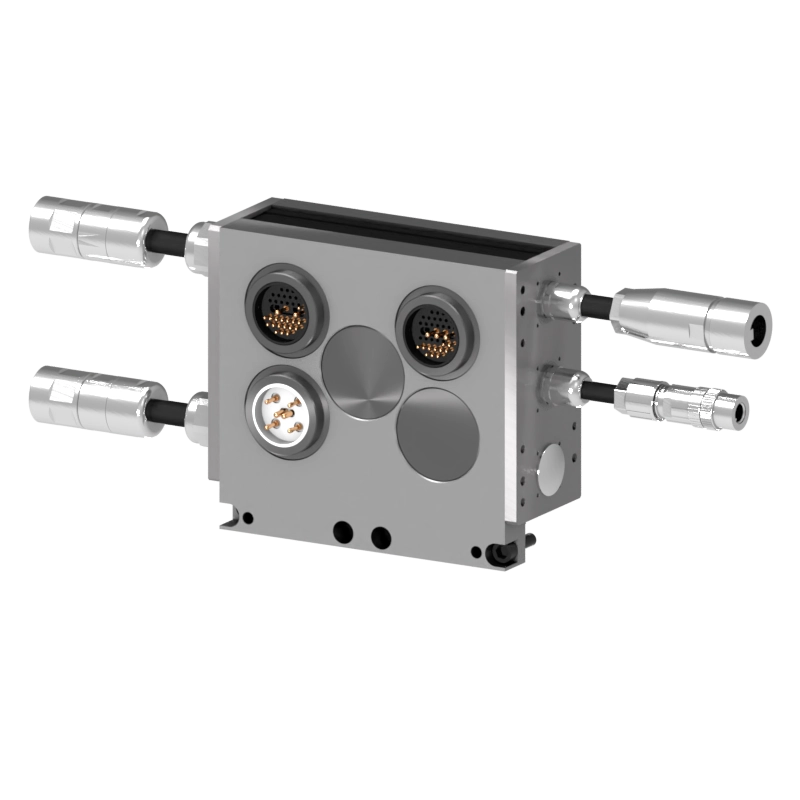

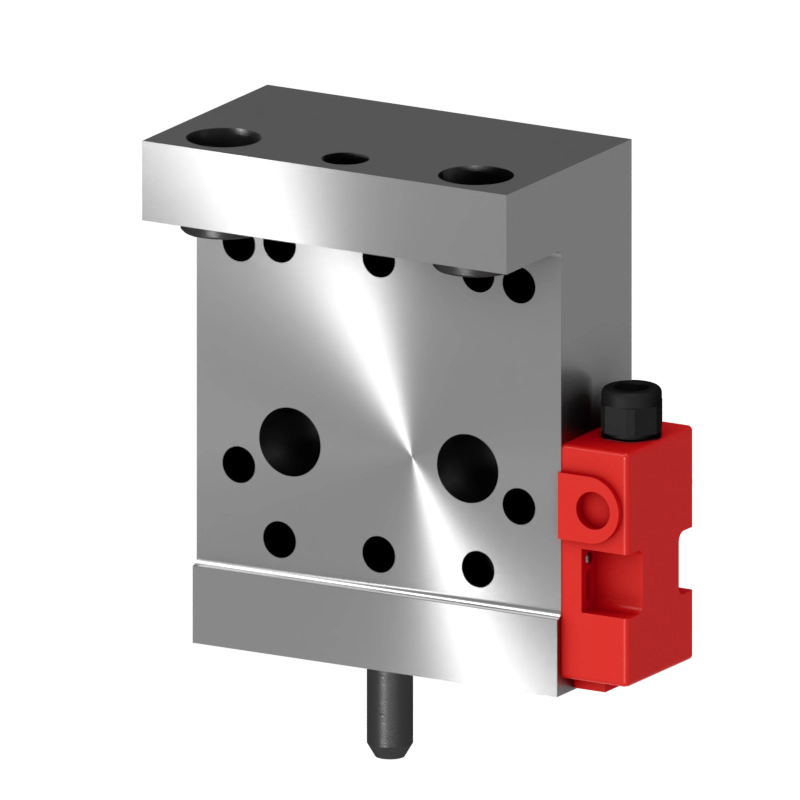

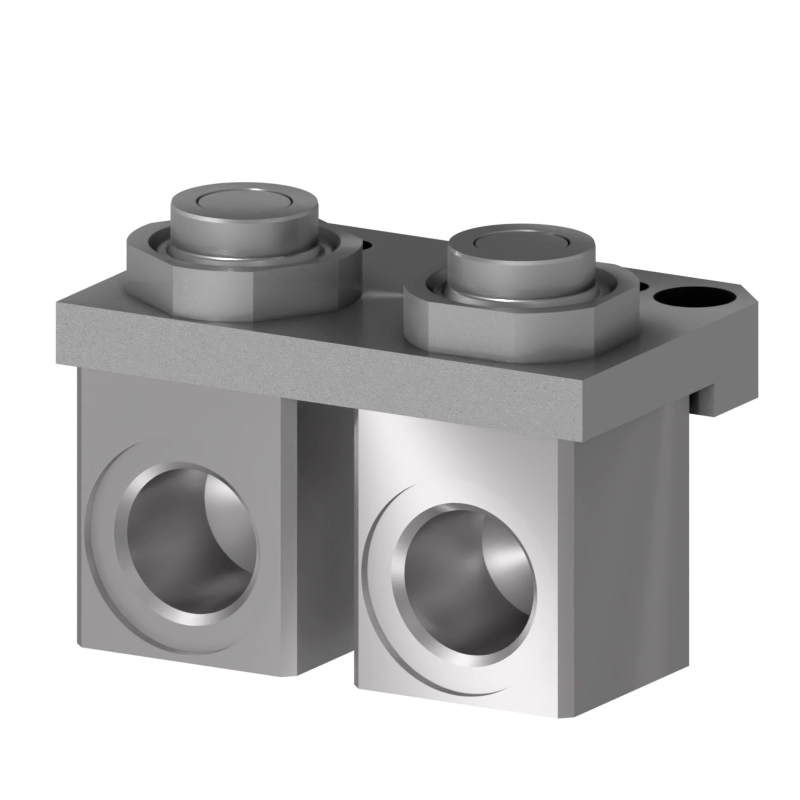

Sigma Series tool changers have a modular design allowing them to suit any kind of application. Indeed, our range of standard module coupled with our custom modules offer increase the Sigma tool changers capabilities enabling them to meet many different needs.

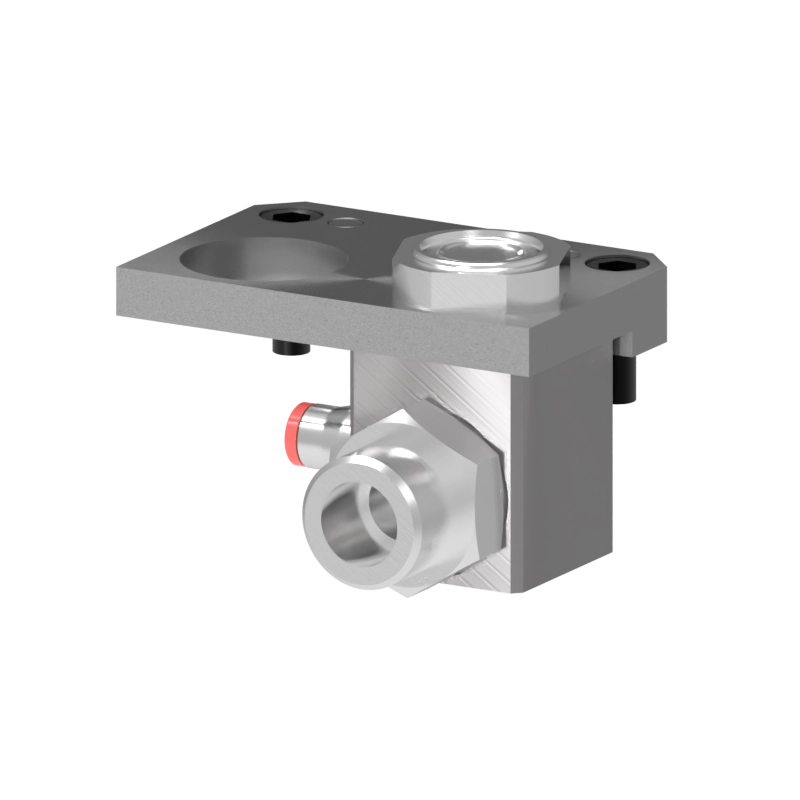

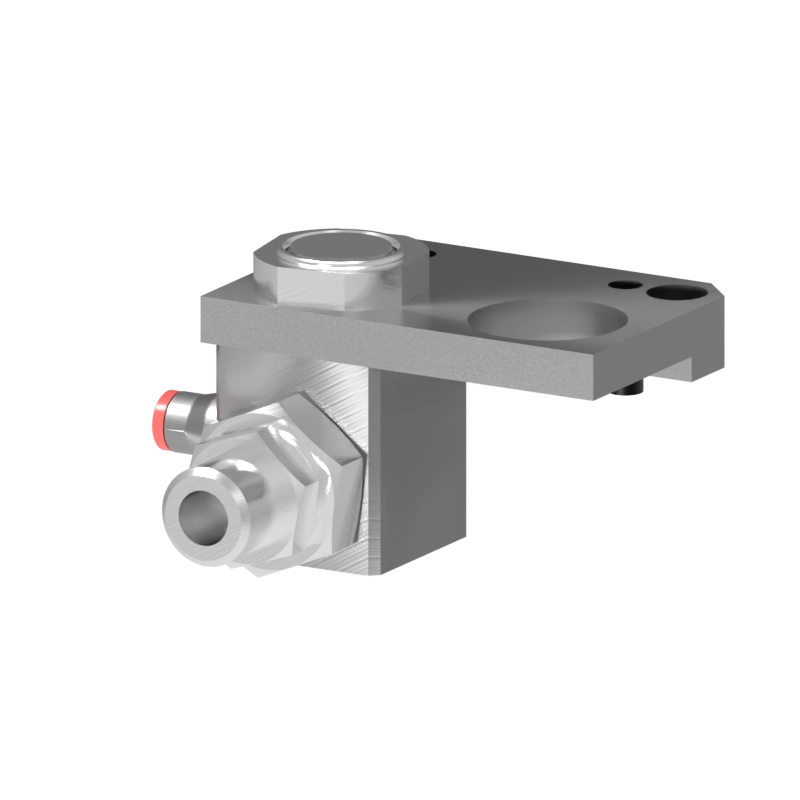

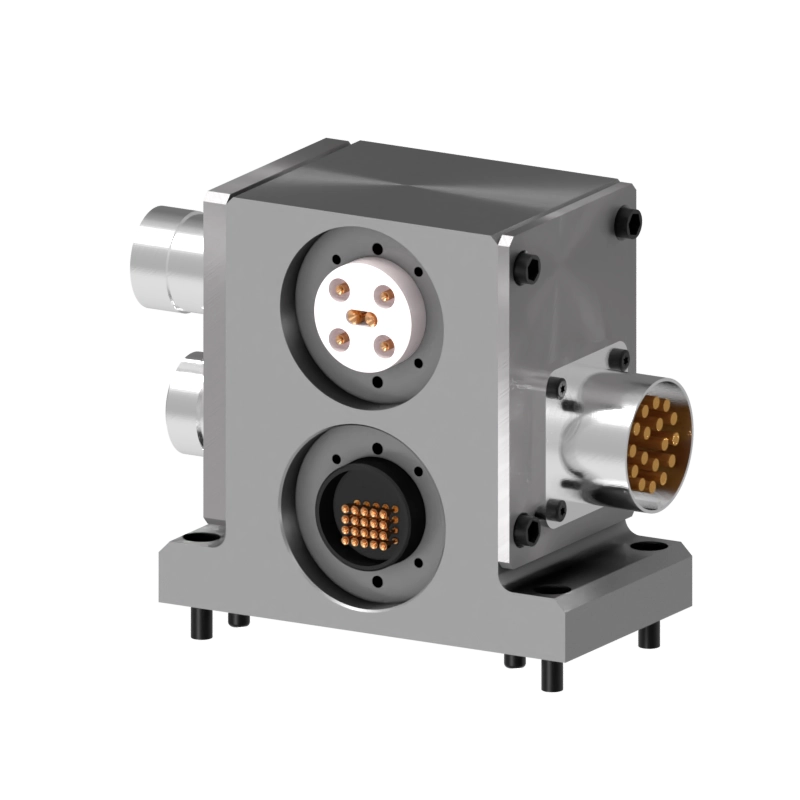

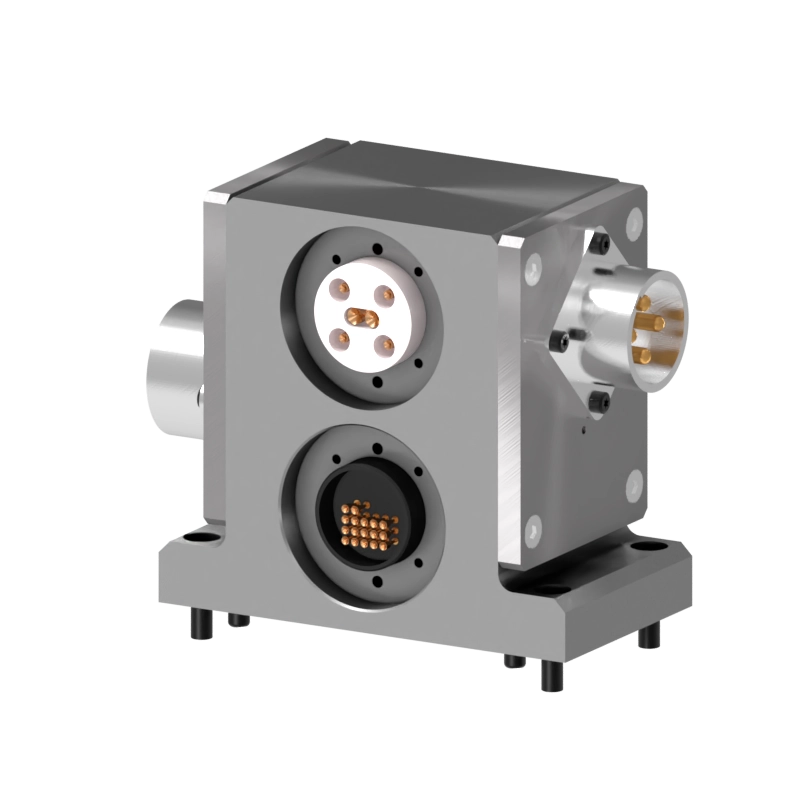

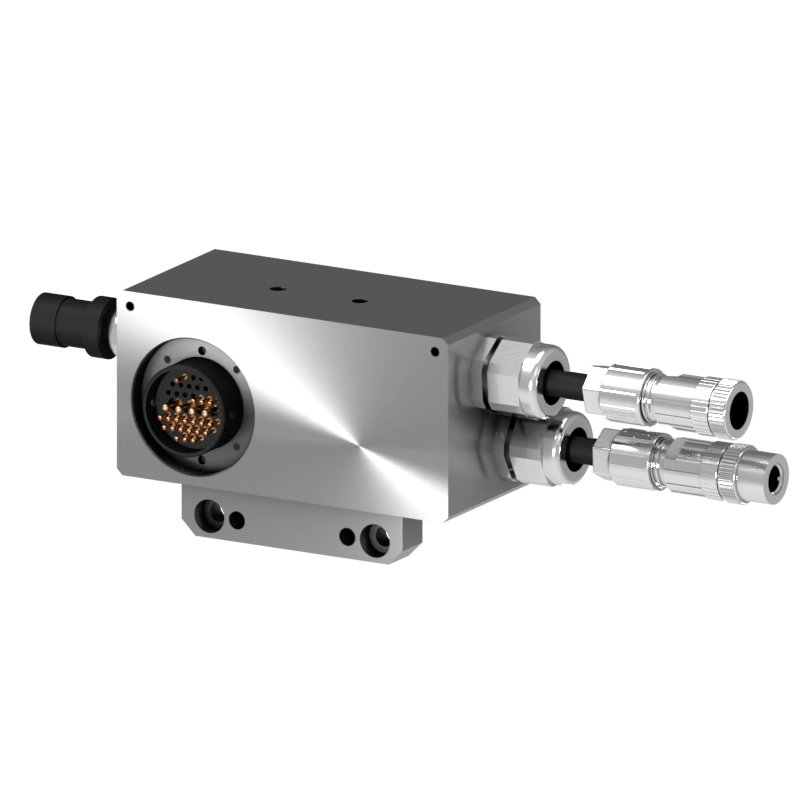

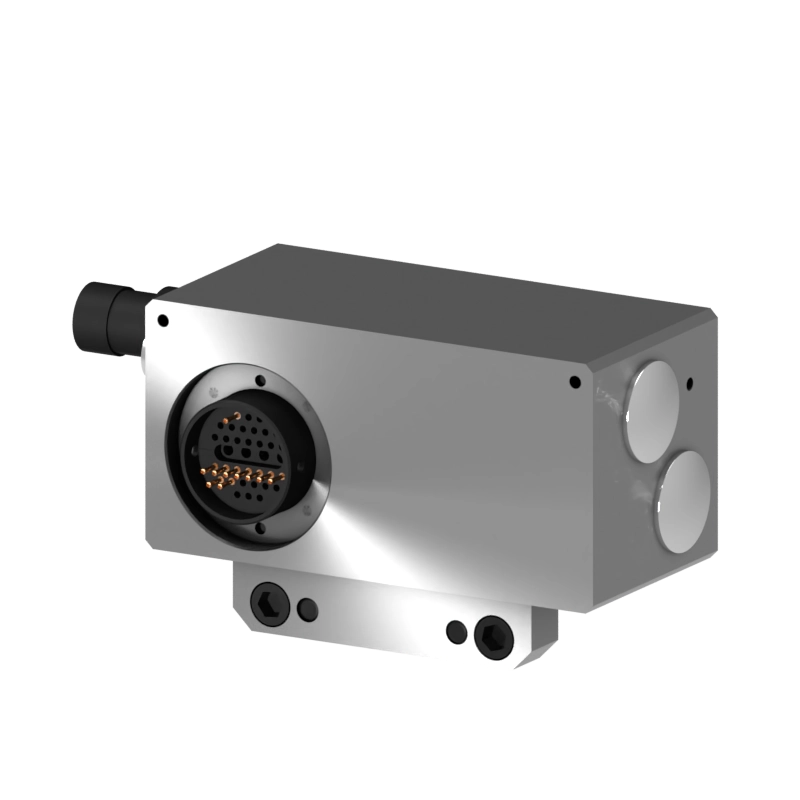

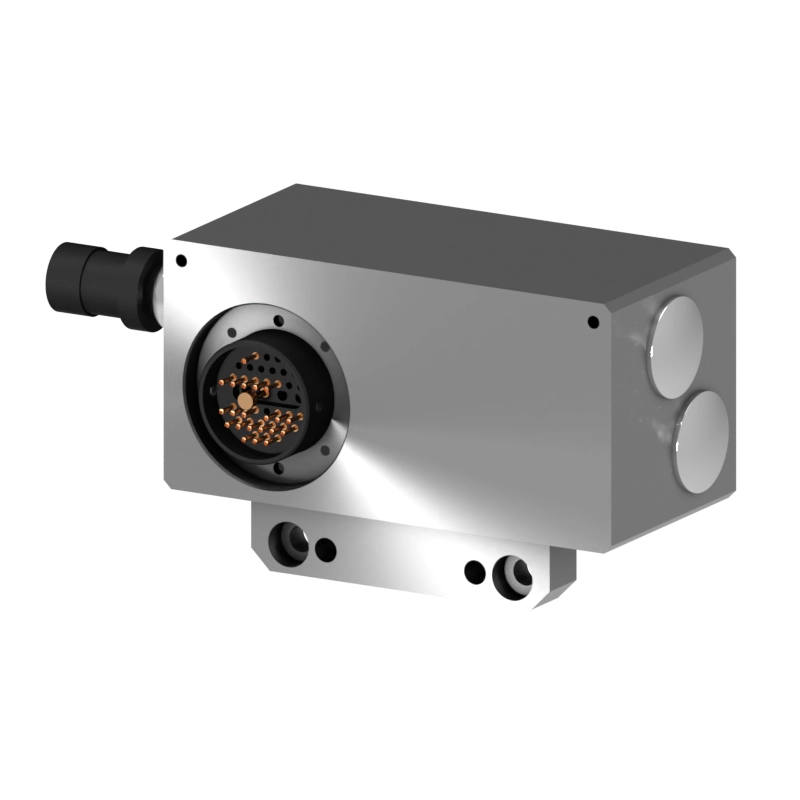

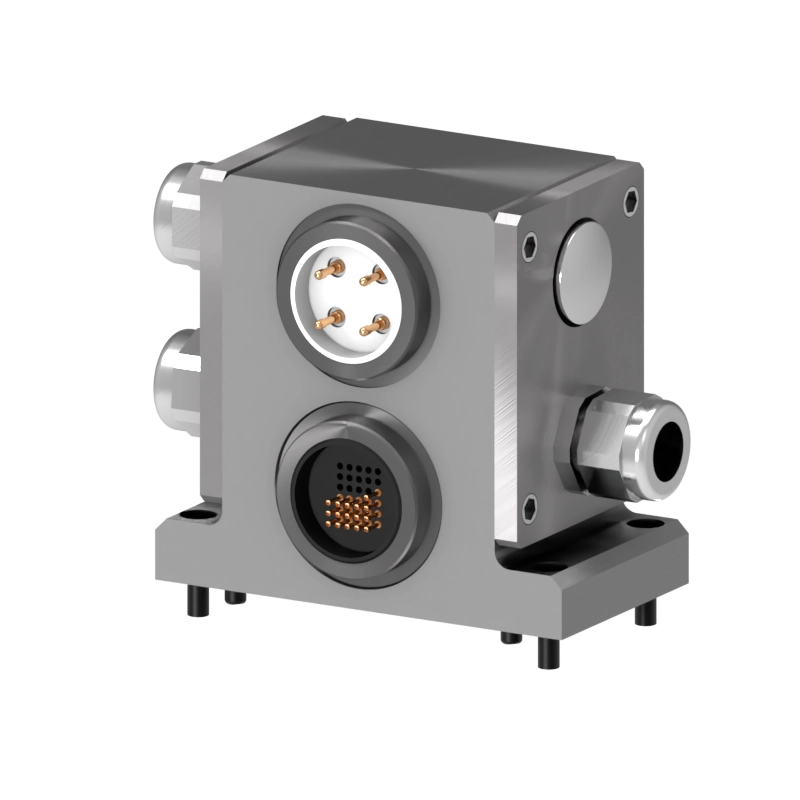

Sigma 8.1 tool changers have a unique six-sided design allowing to accomodate more utilities. The wide range of supported communication systems and their ability to connect directly to your robot face plate, elminitaing adaptor plate make them a easy-to-integrate solution while meeting the most complex applicative needs.

Advantages

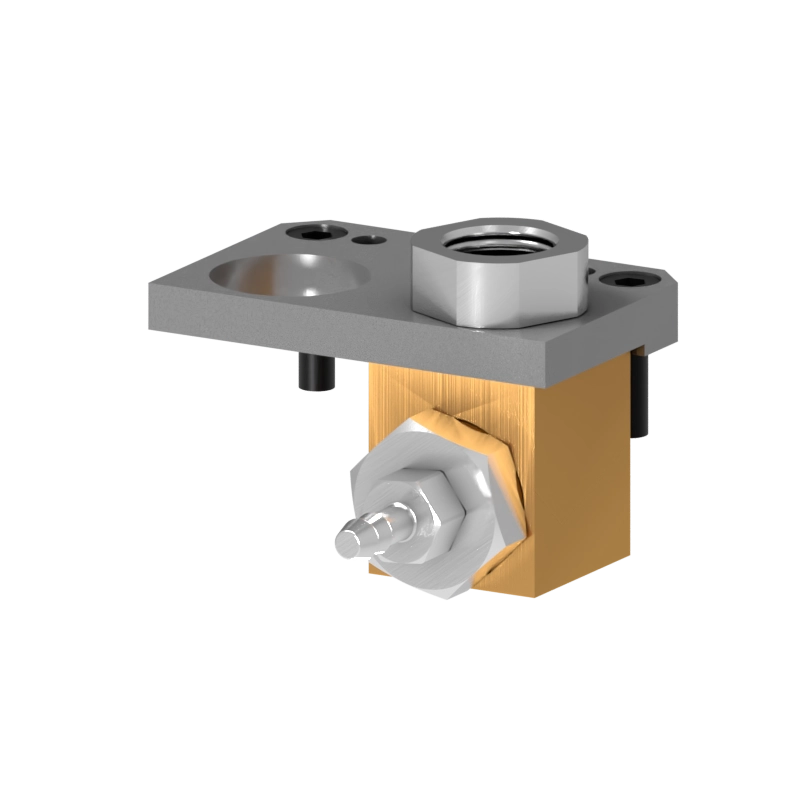

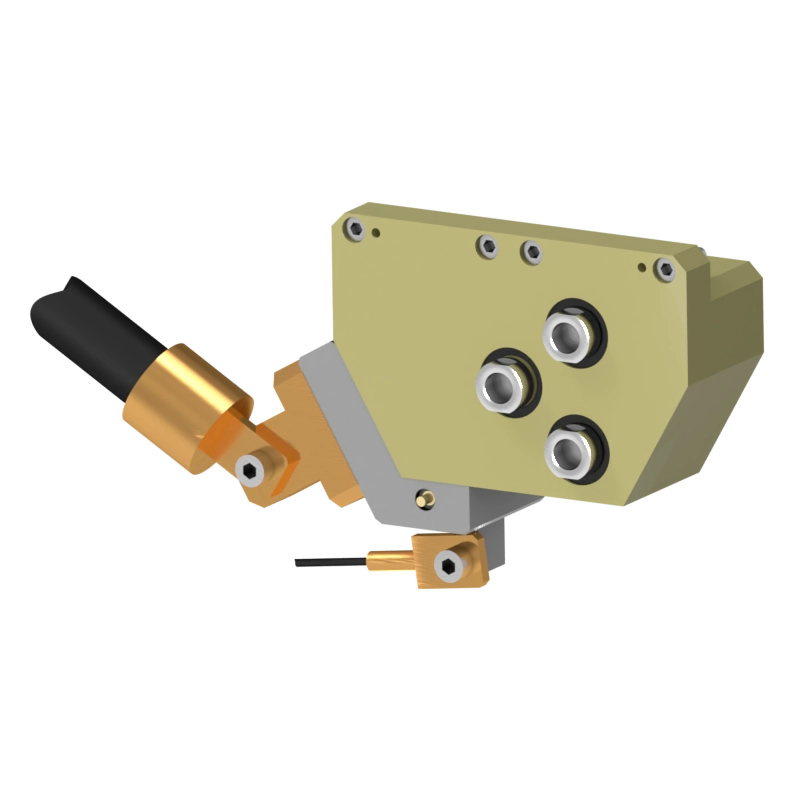

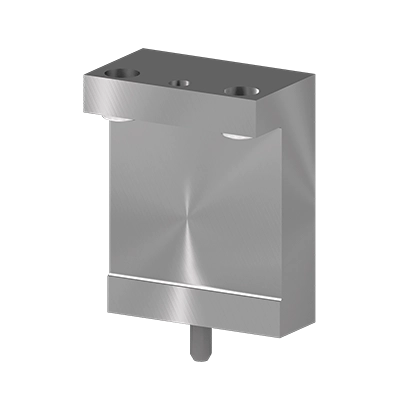

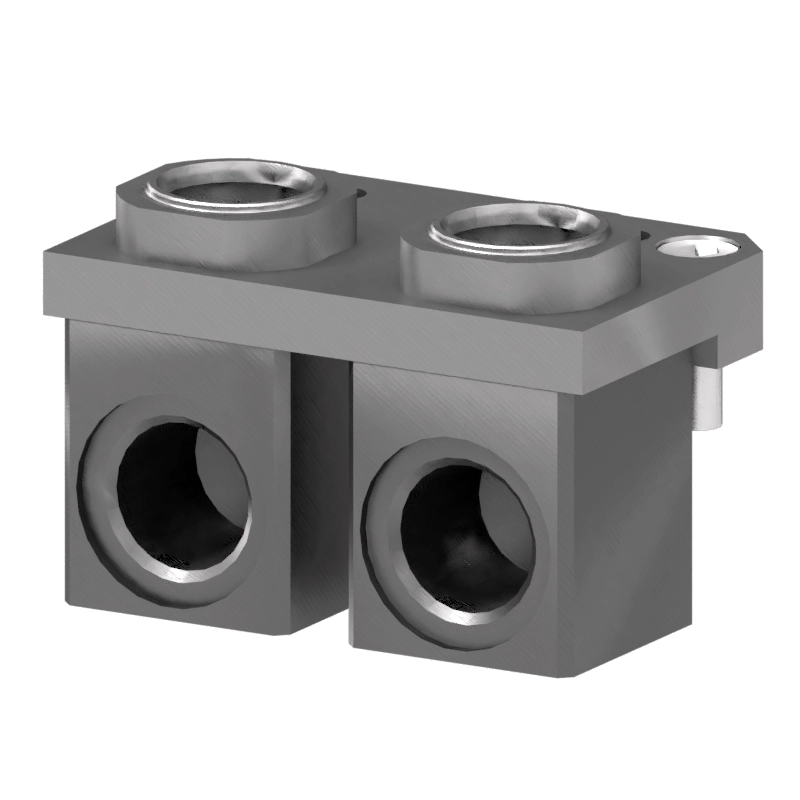

- Unique wear-compensating, fail-safe cam latching mechanism

- Emergency manual unlock feature

- Higher payload capacity – up to 800 kg

- Unique six-sided design accommodates more utilities

Benefits

- A Sigma 3.1 and Sigma 5.1 common profile provides modularity and allows for interchangeability of utility modules

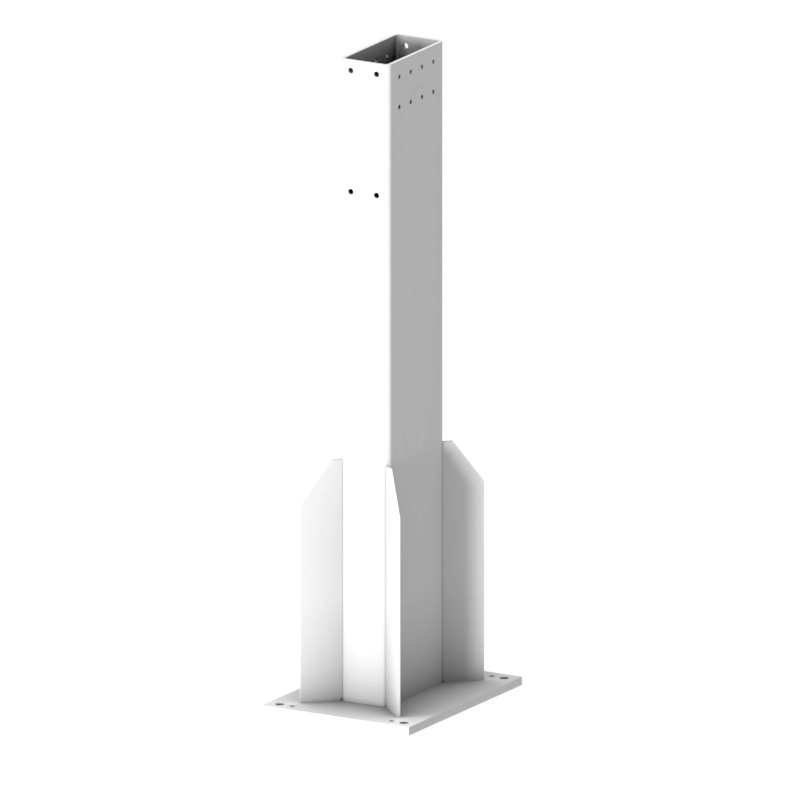

- Eliminates adaptor plates for lower weights, and increased strength and efficiency

- Low profile reduces inertial forces

- Supports wide variety of servo tools and bus communications